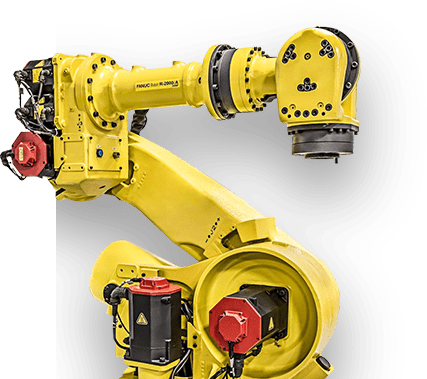

Robotic Palletizing Systems

Custom Robotic Palletizing Solutions

With 100 years of combined expertise in industrial automation system integration and design, Acieta has integrated over 10,000 systems worldwide for manufacturers across a wide range of industries.

We specialize in designing custom palletizing systems tailor made to your specific needs. Each of these systems integrate with existing WMS/MES systems for tracking production data through our systems and have an average 85%+ OEE. Some use cases / key components from past projects include:

|

|

|

|

|

|

|

|

|

|

|

|

Discover how we integrate fully automated pallet conveyor systems, bag palletizing robots, case palletizers, robotic case packers and other advanced palletizing solutions to optimize your operations.

Looking for something specific? We’d love to hear from you! Our team is ready to help you find the ideal palletizing solution based on your specific needs.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones:

Ready to Streamline End-of-Line Production? Contact Us Today!

Discover the ideal robotic palletizer for your operations.

Whether you’re planning a project or just exploring ideas, we’re here to help. Fill out the form and get tailored recommendations from our subject matter experts.