Using robotics in the healthcare industry isn’t just about robotic surgery. For the manufacturing of medical devices, accessories and pharmaceuticals, flexible automation is used for packaging, assembly and inspection tasks to improve consistency, lower costs and maintain aseptic environments.

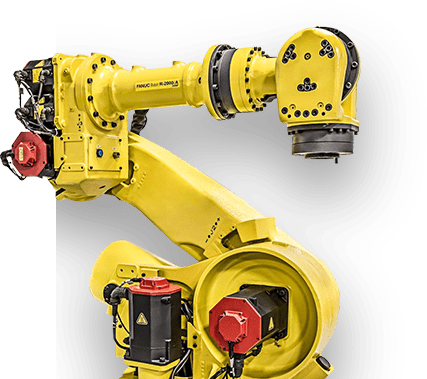

Medical Robotics

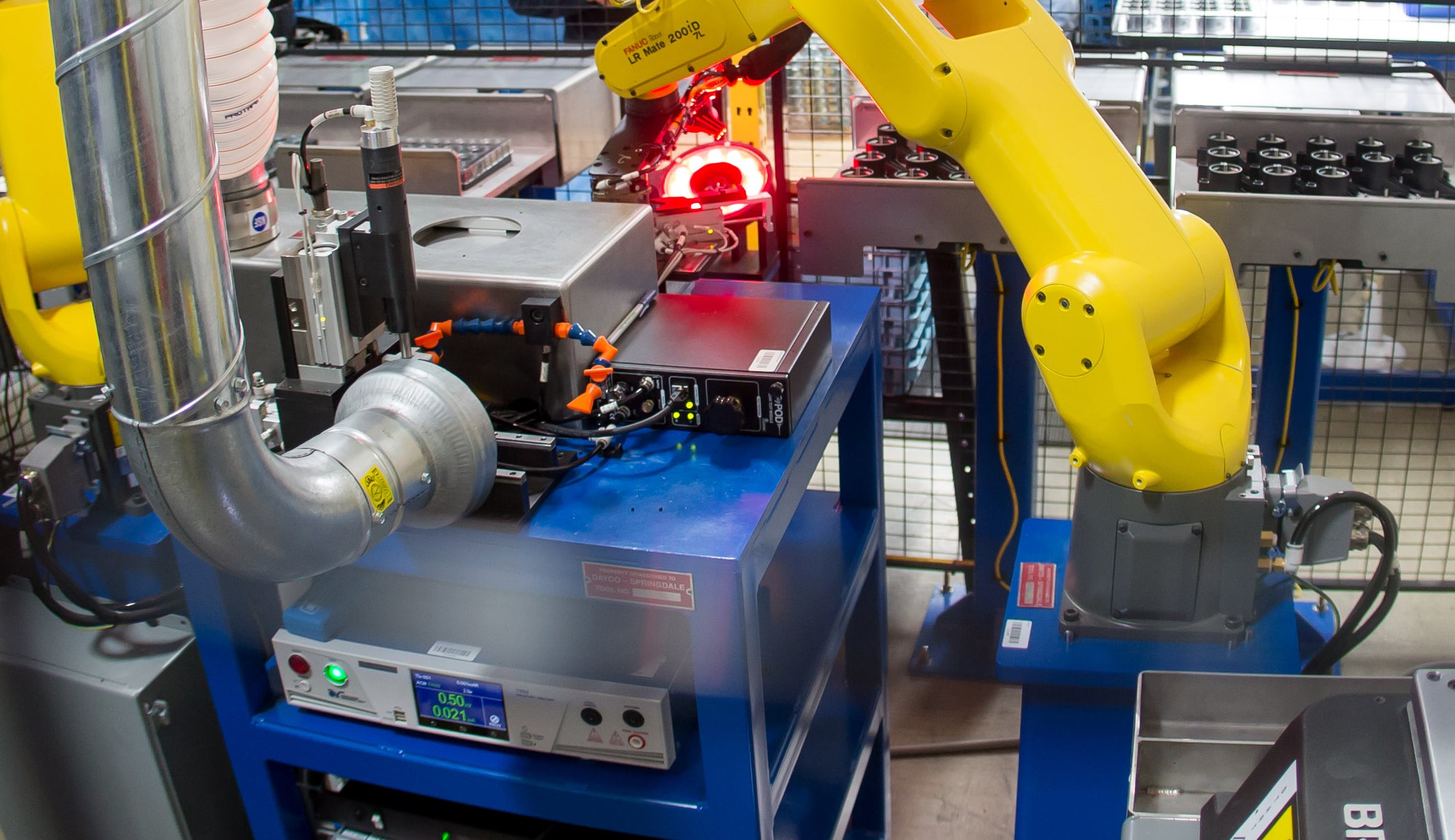

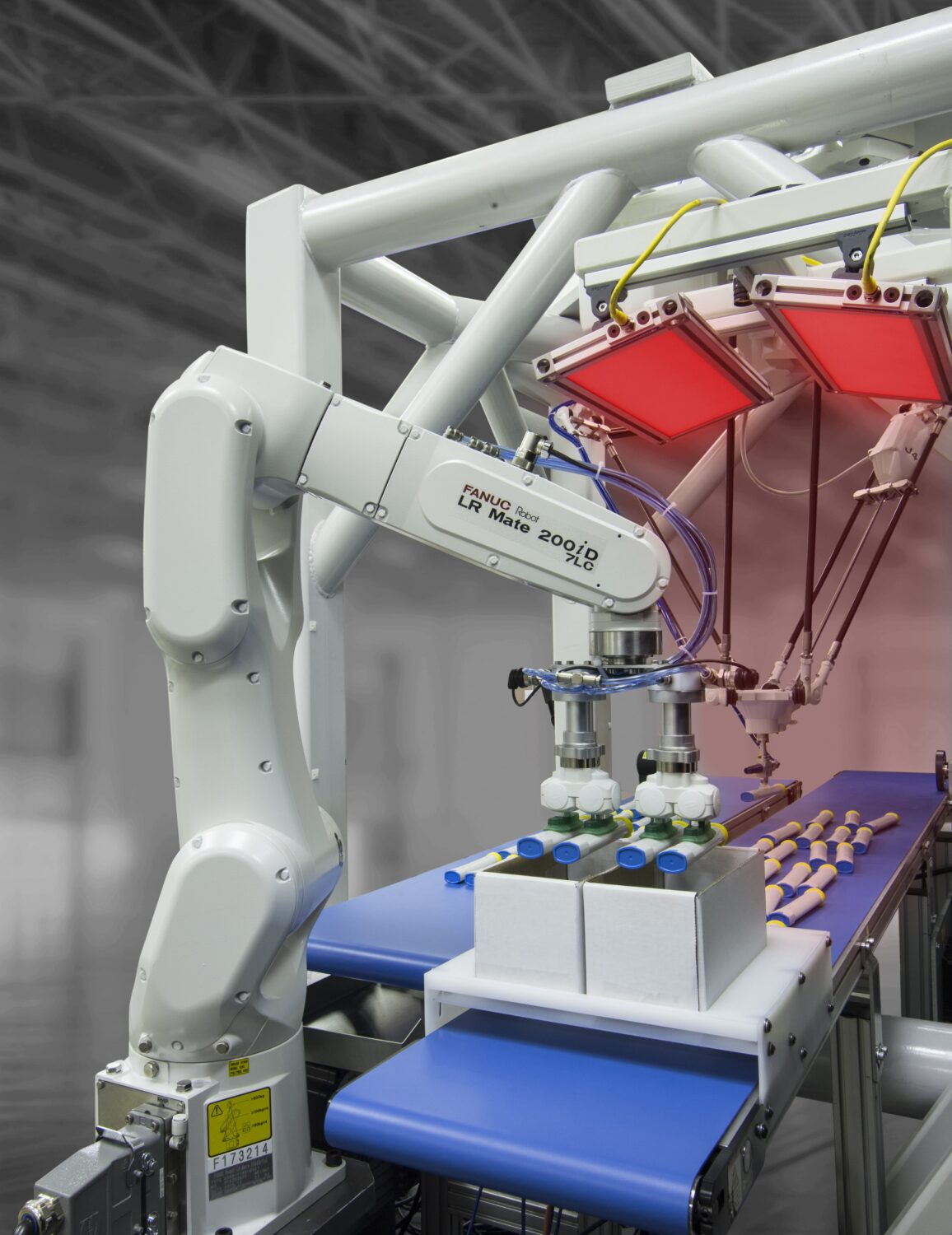

Often aided by vision or force-sensing technology, a robot can change to different product or pack formats in just seconds. Changeover time for packaging and medical assembly robots can be just minutes, sometimes only seconds. In many cases, all it takes is to load a new program, so robots are ideal for shorter production runs. More extensive changeovers can usually be handled with quick-change, end-of-arm tooling. Additionally, if a product line is eliminated completely, the robot can be redeployed to a different task.

Medical Robotics Applications

Medical robotics companies offer solutions for tasks like device assembly, labeling, picking, packing and inspection. Robots are generally smaller, faster and more accurate machines, offering increased capacity and long-term ROI. Here are some of the best-suited application areas:

- LABELING PACKAGES RANDOMLY ORIENTED ON A CONVEYOR – Using vision for package location on a moving belt avoids costly part presentation devices that increase changeover time.

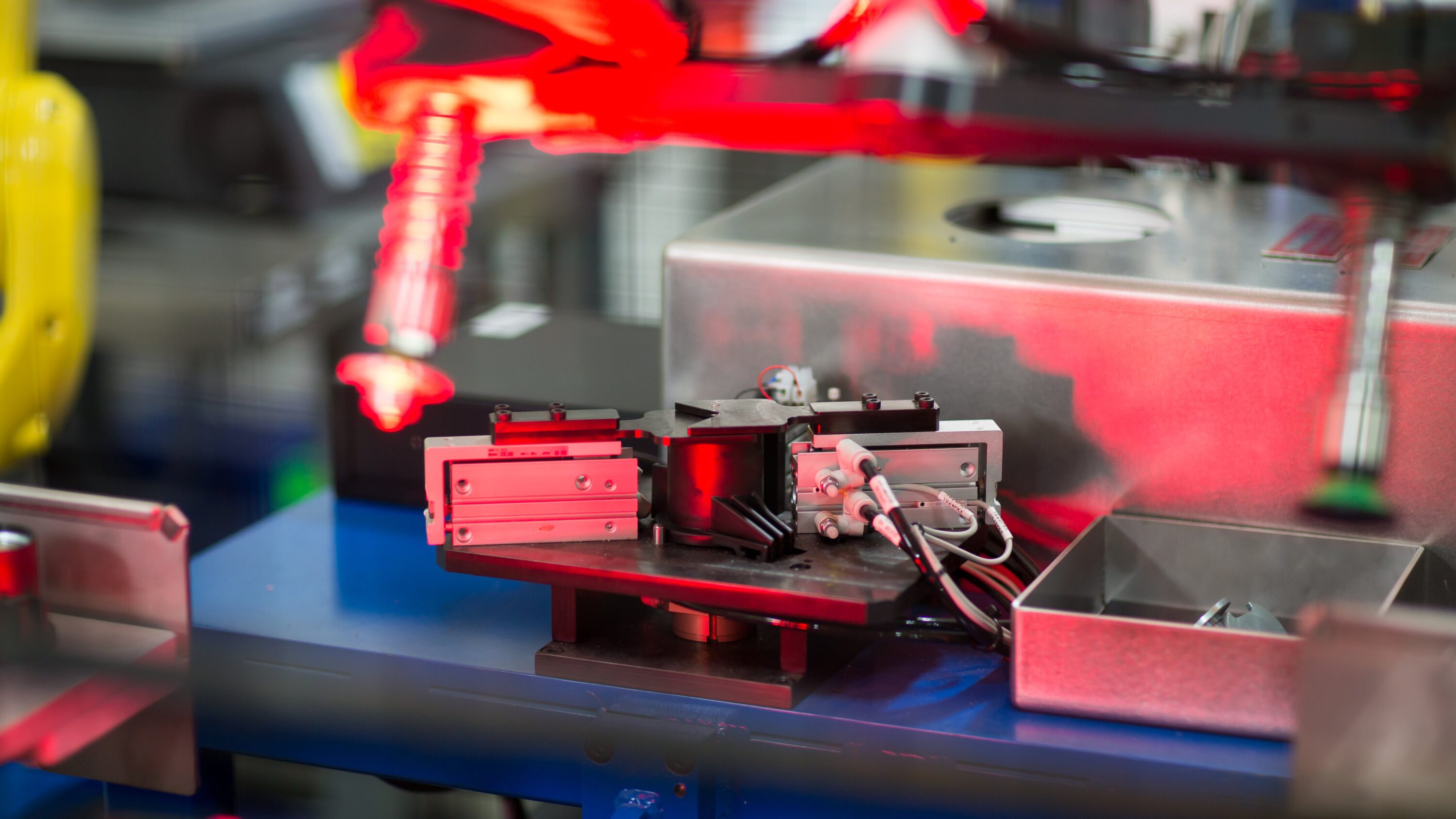

- ASSEMBLING MEDICAL TEST KITS – Force sensing lets the robot adjust to fit issues just as a human worker would. Assembly errors are avoided, and part-to-part variation is recognized and accommodated.

- SYRINGE ASSEMBLY – Size changes between products need only an adjustment in the program rather than expensive new tools.

- TRANSFERRING VIALS BETWEEN TRAYS – Controlled, repeatable motion found in medical robotics prevents damage and spills.

- ASSEMBLY INSPECTION – Mounting a camera on the robot enables close-up inspection of kits, ensuring all orders are correct and complete.

- SEALING – When applying adhesives or sealants with robotic medical technology, the result is uniform thickness or bead width. Since there is no assembly variation, every kit is packed identically, and the customer gets the exact same product each time.

- PALLETIZING – Lifting, twisting and bending are leading causes of musculoskeletal disorders. Giving tasks like those to a palletizing robot protects employees from potential injuries and frees them to concentrate elsewhere.

Whether you’re in medical manufacturing or another industry, Acieta’s robotic automation solutions can help your business, identify opportunities and support you through every step of your project. Get started by contacting us today.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: