Add a vision system to a robot and you give it eyes. The robot can now find objects in its working envelope — reducing the need for complex and expensive fixtures. This increases the flexibility of robotic automation, adapting to variation in part size, shape and location — ultimately reducing cell complexity. By adding a vision system, robot palletizing and de-palletizing becomes practical, components can be assembled, dies unloaded, and parts lifted off racks and out of bins. It’s even possible to track and pick parts in motion on a conveyor.

In order to be effective, a robotic vision system must be installed correctly and should coordinate with existing machinery and work cells. An integrated vision system ensures that the robot’s function will be accurate, efficient and make the biggest impact on your processes. Your robotic installation should include a control cabinet, connected hook-up cables, setup and operation training.

How Do Robotic Vision Systems Work?

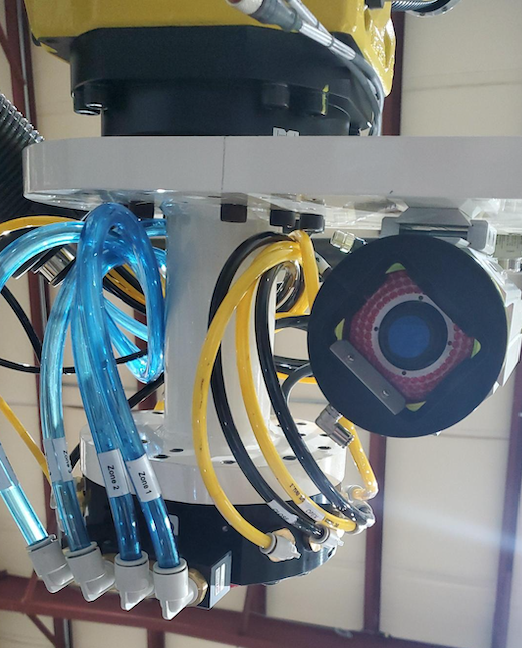

Robotic vision systems consist of cameras, special-purpose lighting, software and one or more robots. The camera and software combination works together to capture an image of the object that the robot grips, while analyzing the image to determine position and orientation. This process occurs on a rapid and continuous basis to drive the technology behind robot vision system applications. Robotic vision software, hardware and controllers work together through assemblies to simplify programming and operation.

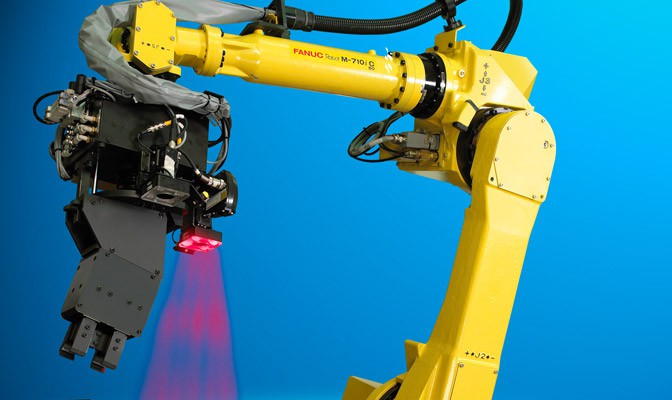

Most vision-guided robotic systems only need X- and Y-axis information, plus rotation, while some also need height information — such as when loading or unloading a pallet. Robotic vision systems can be easily customized to account for these needs, either through onboard cameras or laser-guiding systems.

FANUC 3D robot vision systems are best-in-class solutions that utilize an integrated scanner to analyze and interact with all three dimensions of an application, providing major productivity benefits. We offer engineering and installation expertise to ensure that you get the most out of your system.

Robotic Vision System Applications

Vision-guided robotic systems are often useful in conveyor-driven packaging applications. A FANUC vision system determines accurate belt position and speed through a robotic cell on a conveyor, enabling the system to analyze, track and pick while pieces remain in motion. Additional fixtures are not required, and the conveyor remains in constant operation, enabling a simplified cell design and lower costs since pieces need not be in the same position and orientation every time. The increases in productivity and efficiency make it easy to justify and recoup the expenses of an automated robotic vision system.

Industrial vision systems also offer other advantages. Their flexibility gives manufacturers a great deal of adaptability in their floor layouts, with robot cell complexity kept to a minimum. Because the cameras never tire or become distracted, there is a much lower chance of error and therefore higher overall product quality. They also have the ability to recognize a wide range of parts and can switch over instantly without needing to be reprogrammed. They can handle a large number of part variations and can operate for long periods of time. This means machine vision applications are virtually limitless. Some of the most common functions of vision systems for manufacturing include material handling, palletizing, material removal, and welding and fabrication. If you would like to learn more about what vision-guided robotics systems can do for you and your operations, contact Acieta today.