What are cobots? A cobot, or collaborative robot, can safely share a workspace with people. This is different from traditional robots that are isolated by safety fences. With the growth of sensor and controller technology, a cobot can reliably detect and adapt to intrusion in its work envelope, so physical barriers are not essential for safe operation.

A cobot will have one more of these safety features:

- Safety-rated monitored stop

- Cell-hand guiding

- Speed and separation monitoring

- Power and force limiting

Cobots employing the power and force limiting approach protect against impacts but can limit speed, accuracy and payload compared to traditional robots. Other cobots employ speed and separation monitoring and safety-rated monitored stop strategies via controller and sensor features, such as FANUC’s Dual Check Safety (DCS) system.

When deploying cobots, it is still essential to conduct a formal risk assessment before ditching the fencing. The tool being carried or other aspects of the process may still require guarding, which can limit what cobots are used for.

Advantages of Cobots

Details depend on the application, but in general there are several benefits of collaborative robots compared to traditional robots.

Less Floorspace

A traditional robot used in an automated cell must be guarded to keep operators outside. In addition, other equipment is needed inside the cell for part presentation, and conveyors or other feeding systems are needed to move work in and out. All of this is eliminated by using a cobot.

Lower Cost

Guarding is expensive, especially when gates, interlocks and interfacing to the cell controller are included. However, there’s a cost of moving material in and out of the cell as well. While simple roller conveyors might be inexpensive, belt and pallet systems can add significantly to the cell's cost; but with a collaborative robot, an operator can work alongside the automation, positioning the material or workpiece and removing finished pieces from the cell.

Easy Programming

Many cobots can be programmed by hand-guiding them through the path needed. Programming is done offline or via a teach pendant, making a cobot something many workers can quickly learn to use. This eliminates the need for a programming specialist.

Higher Productivity

Cobots can work continuously 24/7, even in some lights-out environments. Plus, the cobot can work on moving and positioning parts while a person focuses on tasks that need dexterity and adaptability. This increases output from the worker, which is one of the goals of robotic automation.

More Flexibility

Collaborative robots also permit more flexible manufacturing practices. This comes about in two ways: as a result of eliminating the guarding, and through the ability to quickly reassign the cobot a new task.

Considering guarding, a problem with traditional robots is their limited ability to handle unexpected events. Take a robotic palletizing application: if one sack or bag shifts, it could destabilize the whole pallet. Without collaborative capabilities, the robot would shut down for the operator to enter the cage. When restarting, depending on the programming, it may need to begin the cycle again with an empty pallet.

In contrast, a collaborative robot would summon assistance and pause. The worker would quickly adjust the stack on the pallet and let the cobot resume, which reduces downtime.

Similarly, consider a material removal cell where a robot is trimming metal or plastic moldings. Excess material builds around the tool and workpiece and pushes the material away from the tool. In a collaborative setup, a human operator can step into the cell and the cobot will pause while the buildup is removed. Then, with the operator safely out of the way, production will resume.

The ease of programming and absence of guards mean it’s possible to quickly give a cobot a new job. To take advantage of this, the cobot can be mounted on a cart that is moved to machines as needed. This mobile cobot is a cost-effective way of automating many machine tending and pick-and-place tasks.

Improved Quality

Cobots are reliably repeatable. Once taught a path, they will follow it without fail, which eliminates human errors. Power-and-force limited cobots have the additional advantage that they can sense if something prevents them from moving to a target position. This is especially useful in assembly tasks where, rather than continuing to push on a part that won’t insert correctly, the cobot can be taught to back off and try again.

Cobot Applications

There are a host of ways in which cobots can increase efficiency, boost productivity and improve safety.

Good applications for cobots in manufacturing include packaging, assembly, palletizing, welding, dispensing and machine tending. Cobots can be quickly taught to pick and place items in response to external signals and can work alongside people.

With traditional robots, the amount of engineering and time needed to set them up for a job makes them best suited for high volume applications. In contrast, short setup times mean cobots are ideal for low volume, high mix manufacturing operations found in many smaller businesses.

Cobot Solutions From Acieta

Acieta helps manufacturers reduce costs and improve quality with robotic automation. We offer a range of cobot solutions engineered to meet the needs of small- to medium-sized businesses.

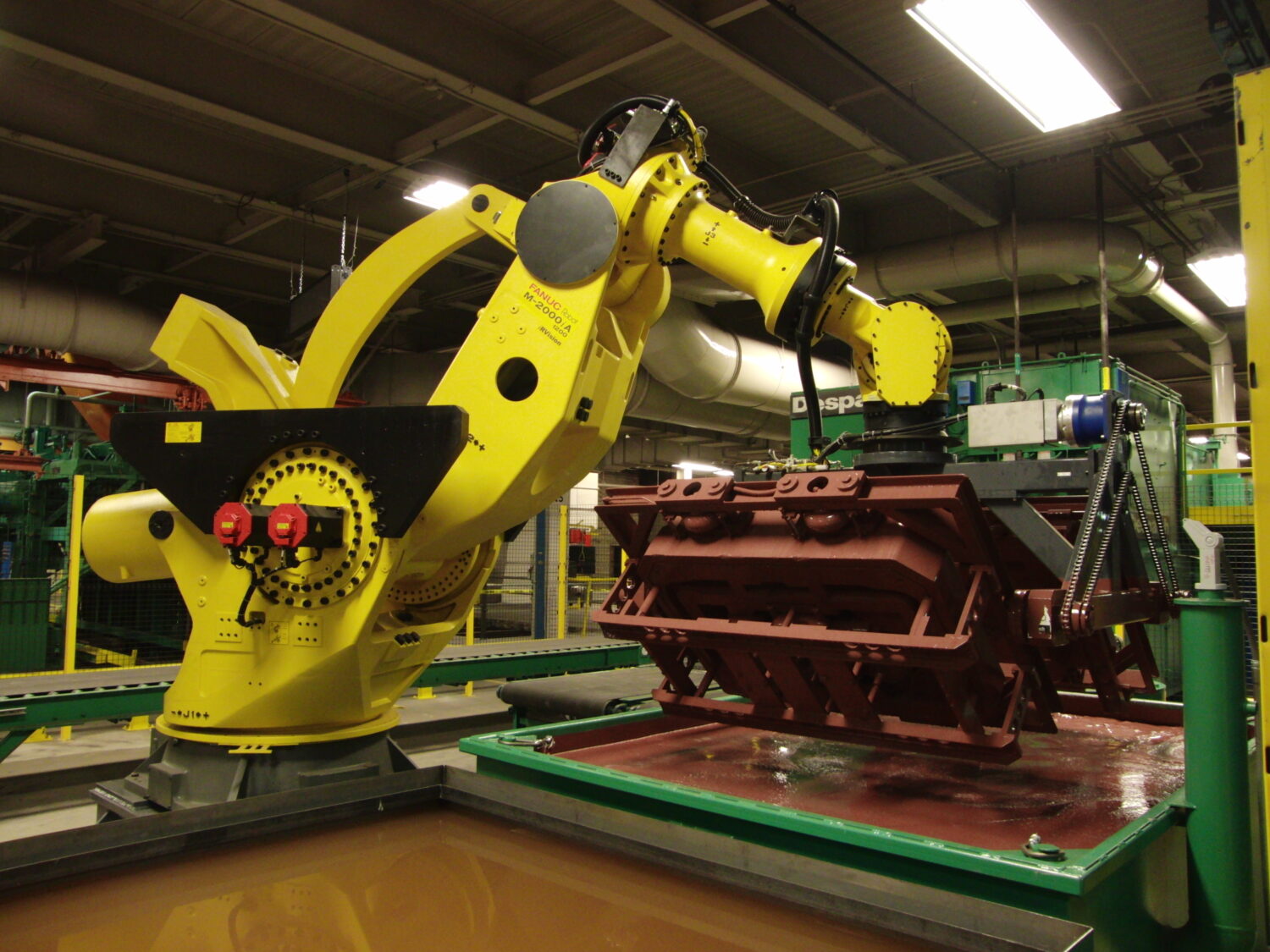

Our FastLOAD CX1000 system is a mobile cobot designed for machine tending. This can be easily moved to different machines as needed and fitted with end-of-arm attachments to perform tasks like loading/unloading. The FastLOAD CR2000 performs the same function for higher payloads.

The FastARC® CX1000 and FastARC® CW cobot solutions perform welding tasks. These deliver consistent weld quality all day longand are mobile if you need them to do a different welding job elsewhere.

Cobots are revolutionizing manufacturing. They help small, medium and large companies streamline production, grow throughput and save money. Contact us to learn how we can help you with those goals.