Manufacturers in every industry want to automate, and it’s not just about driving down costs. Automation improves quality and protects workers from hazardous tasks and environments. When used to address skills shortages, it increases capacity, and by enabling companies to reshore work from overseas, it even helps protect intellectual property. Yet, despite the tremendous technology advances made over the last two decades, there’s a mindset that automation requires high volumes, low variety and extended product lifecycles. That’s regrettable, because it means small-to-medium manufacturers, as well as those dealing with short product lifecycles, are missing an opportunity to improve margins.

Traditional automation hardware, like transfer lines and pick-and-place machines, is expensive to engineer, and adding flexibility just pushes the price higher. In a highly stable business where the same product will be made and sold in volume for years to come, it can reduce costs — but many businesses no longer have that luxury. Product lifecycles are often measured in months rather than years, design changes are a way of life, customers want even more variety, complexity and customization. What’s more, demand can shift suddenly based on the whims of weather, fashion or competition. Robotic automation addresses these challenges, enabling economic short runs, consistent completion of complex tasks, and replacing humans in hazardous or unpleasant work.

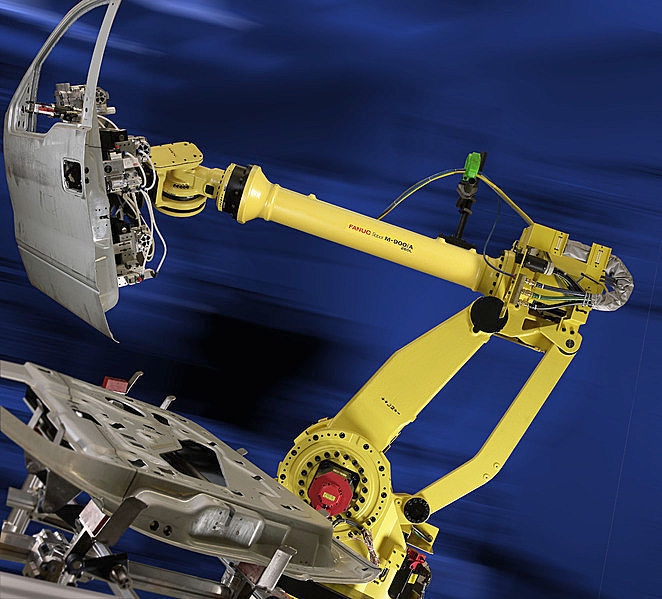

The flexibility of robotic automation makes it the right technology for companies dealing with short runs and high variety. With the proper configuration from an experienced integrator a robot cell can often be changed over from one part to another just by loading a new program, especially when hard fixtures are replaced by vision systems that locate parts in the work envelope. Tool changes can be programmed, too — letting a robot change part grippers or pick up a new tool, even during a cycle. Potentially, a robot could work on one-offs, changing over to the next job with almost no stoppage time.

There’s almost no limit to the complexity of tasks a robot can be programmed to do. Welding is one example. In an advanced welding system, one or more robots can work with components like tilt/rotate tables that add additional axes. This lets a robot present a torch to the workpiece or joint at the ideal angle, and from whatever direction works best, producing a high-quality weld, every time. Another example of a complex task is assembly. In these applications, robots can perform complicated and delicate assembly tasks, especially when equipped with force sensing to aid the insertion of one component into another. Assembly steps can be combined too, reducing floorspace when compared with hard automation.

Robots are ideal for work that’s potentially hazardous to human health. Used in a material handling application, a robot protects works from the musculoskeletal disorders that often result from repeated lifting and twisting. Or consider dusty or fume-laden atmospheres and noisy environments. In all these situations, using a robot protects employees, reducing the risk and cost of injuries. Whatever type of manufacturing business you’re in, robotic automation may be the right choice for you.