October 29-30, 2024

Council Bluffs, IA

Gain Your Competitive Edge

Dominate the Market with Game-Changing Automation

In the fast-paced world of manufacturing, staying ahead of the competition is like a high-stakes sports tournament. To secure your victory, you need to gain your competitive edge, and that means embracing robotic automation.

The future of manufacturing is a fierce competition, full of opportunities for those ready to take the lead. To remain globally competitive in an ever-changing environment, it’s crucial to gain your competitive edge by integrating cutting-edge robotic automation.

Whether you’re well into your automation journey and looking to upgrade and optimize your systems, or you’re just starting out and exploring the possibilities for the first time, this event is designed for you. Automation is a complex and evolving field, and our goal is to provide valuable insights and solutions tailored to meet the needs of all attendees, regardless of their experience level. With informative presentations, interactive breakout sessions, and networking opportunities, we’re excited to help you secure your competitive edge through automation.

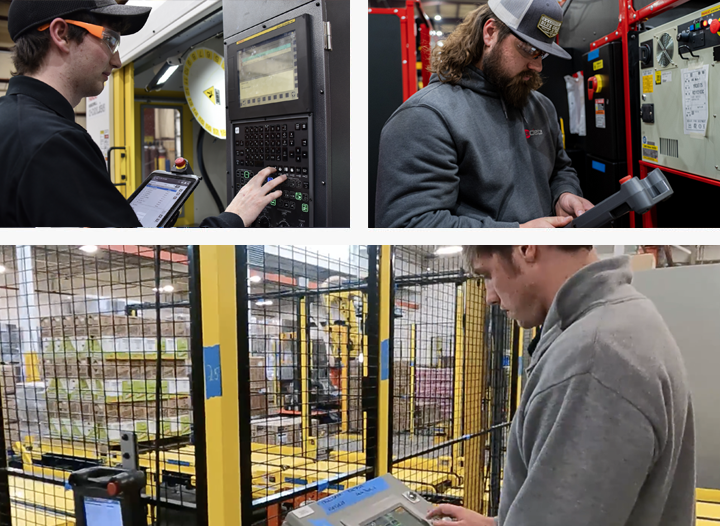

Join us for a two-day hands-on experience with state-of-the-art robotic systems, and hear from industry leaders about their own successes with automation. Witness live demonstrations of robots tackling diverse challenges, and discover how robotic solutions can give you the edge you need to succeed in an evolving industry.

At this year’s invite-only Celebrate Manufacturing event, we’ll dive deep into the challenges of the manufacturing industry and the advantages of robotic integration for your specific situation.

Your invitation grants you exclusive, VIP access to:

- One-on-one discussions with world-class experts to answer your questions about preparing for the future

- Hands-on experience controlling a robot

- Breakout sessions

- Networking with other, non-competing manufacturers facing similar challenges

Bring your questions, goals, and imagination to this exciting event, and discover how robotics can help you overcome production and hiring challenges.

This is an exclusive opportunity to gain your competitive edge and score big with robotics.

Agenda

October 29, 2024

1:30 p.m. Check-in

2:00 p.m. Kick-off

2:30 p.m. Plant tour

4:00 p.m. Breakout session 1 (40 min)

4:50 p.m. Breakout session 2 (40 min)

5:30 p.m. Cocktail hour begins

6:00 p.m. Dinner and games

October 30, 2024

7:30 a.m. Welcome and breakfast

8:30 a.m. Panel

Hear from an industry-expert led panel discussing the state of automation and best practices in manufacturing.10:00 a.m. Break

10:15 a.m. Breakout session 3 (40 min)

11:05 a.m. Breakout session 4 (40 min)

- 11:45 a.m. Regroup and recap

- 12:00 p.m. Box lunch

Experts will be available on Wednesday afternoon for an individual strategy session. Slots will fill up quickly. If interested, please contact marketing@acieta.com.

Location:

Acieta

2096 21st Ave

Council Bluffs, IA 51501

Breakout Sessions

Connecting Manufacturing to AI: A 30-Minute Crash Course

Mark Dowd, General Manager, Acieta | +Vantage

In an era where efficiency and innovation are paramount, understanding how to leverage artificial intelligence (AI) in manufacturing is crucial for staying competitive. This breakout session offers a concise yet comprehensive introduction to the transformative potential of AI in the manufacturing sector. Participants will explore practical applications such as predictive maintenance, quality control enhancements, and supply chain optimization, demonstrating how AI can address common industry challenges. We will also outline the initial steps for effective AI integration, including data collection strategies, solution selection, and the development of pilot projects. Join us for an interactive discussion designed to help you uncover specific opportunities within your operations and begin your journey toward a smarter, more automated manufacturing future.

Winning the War for Automation Talent

Matt Kirchner, President, ATS/Lab Midwest

Educators across the Midwest have heard the message. American advanced manufacturers can compete and win globally, provided they have the best talent.

In this thought-provoking presentation, Matt Kirchner, host of The TechEd Podcast and President of FANUC’s leading Education Solutions Provider will share the 5 key strategies the most innovative manufacturers are employing today to win the war for talent.

From AI to automation to robotics to career-building certifications, what’s being taught in some of our high school and technical college manufacturing programs will blow the minds of even the most cutting-edge manufacturing companies. Get “in the know” and access the talent you need to lead your industry.

Key Trends in the North American Robotics Market

Alex Shikany, Vice President, A3 Assoc for Advancing Automation

This illuminating session delves into the dynamic landscape of the North American robotics market. The latest statistics will provide a comprehensive snapshot of the industry’s current state, setting the stage for deeper insights. Recognizing that robotics doesn’t exist in a vacuum, the presentation will also explore macroeconomic conditions and key economic indicators impacting the economy and manufacturing sectors, offering a forward-looking perspective on potential shifts and opportunities.

To further enrich the discussion, sentiments directly from the automation industry will be highlighted, showcasing expectations and strategies as the future unfolds. The session culminates with an evaluation of key trends and growth areas, brought to life through engaging video examples that demonstrate real-world applications and innovations. Whether you’re a seasoned professional or new to the field, this presentation promises valuable insights and actionable information to help navigate and succeed in the evolving world of robotics.

Sharpen your Competitive Edge with Integrated Autonomous Mobile Robots (AMRs)

Scott Wagner, Regional Automation Manager, Acieta

In the high-stakes arena of manufacturing, the quest for a competitive edge is more crucial than ever. As companies strive to streamline productivity, safety, and operational efficiency, they are discovering that the integration of Autonomous Mobile Robots (AMRs) is not just an advancement—it’s a game changer. These mobile robots are wheeling new life into traditional manufacturing workflows, providing a distinct competitive edge by seamlessly integrating with equipment and applications for automatic calling, queueing, and hand offs. By harnessing the power of AMRs, manufacturers can stay ahead of the curve and carve out their niche in an ever-evolving landscape.

Cobots: What to know!

Bryan d’Ouville, Director – Sales & Execution FANUC America – Midwest Robotics

Understand what makes a cobot different from traditional robotics, what they can and can’t do, what to look out for, and where they are being utilized successfully.

Fixture Building and Cad to Path Programming Software – How to setup your next welding or cutting job easy, in minutes

Denis Danchine, Automation & Digital Twinning Expert – Digital Factory Solutions (DFS), CENIT

This session would answer such questions:

- What are the challenges of using robots and cobots?

- Why do robots need fixtures (tooling) to hold parts?

- What (tools) are out there to build fixtures?

- How can I apply robots or cobots in fabrication effectively and be more competitive?

- What (tools) are out there to teach (program) robots?

- How can I get my underutilized robot to do more jobs for me, get more bang for the buck efficiently?

- Can I see a hands-on example of setting up a welding job (with minimal downtime & at fraction of the cost) including a weld fixture and robot program?

BIOS

| John Burg, Founder Emeritus, Acieta |

| Denis Danchine, Senior Account Manager, Digital Factory Solutions, CENIT |

| Bryan d’Ouville, Director, Sales & Execution, FANUC America Corporation

|

| Chris Ford, Director of Manufacturing Engineering and Robotics, United Alloy | Panelist Following in his grandfather’s footsteps, Chris began his career in welding. Eventually, he combined his passion for welding with technology and advanced into manufacturing and weld engineering for large scale manufacturers. In addition to Chris’ role as Director of Manufacturing Engineering and Robotics at United Alloy, he is a certified welding inspector and has trained many welders and robot technicians throughout his career at various colleges and manufacturers. |

| Milton Guerry, President, SCHUNK | Panelist |

| Matt Kirchner, President, LAB Midwest Committed to securing the American Dream for future STEM talent, Kirchner hosts the TechEd PodcastTM and serves as President of ATS/LAB Midwest, a leading distributor of curriculum, eLearning, and training equipment. He writes leadership columns for Products Finishing and Production Machining magazines and authored “Teaching the Industrial Internet of Things: Preparing Students and Learners for Industry 4.0.” With over 20 years as an industrial CEO, Kirchner led three top manufacturing companies, selling the last to DuBois Chemicals in 2014. Kirchner serves on several company boards and the board of trustees for the American Technical Education Association and the Smart Automation Certification Alliance. He is a Marquette University School of Business graduate.

|

| Robby Komljenovic, Operating Board Member, Acieta | Panel Moderator |

| Scott Wagner, Head of Autonomous Material Handling, Acieta | RoBEX Division |

| Mark Dowd, General Manager, Acieta | +Vantage Division |

| Alex Shikany, Vice President of Membership & Market Intelligence, Association for Advancing Automation (A3) | Panelist |

RSVP

Contact marketing@acieta.com or call 262-933-0018 with any questions. Fill out the form below to RSVP.

NEARBY HOTELS

Holiday Inn Express and Suites/Council Bluffs, IA

2211 South 32nd Street Council Bluffs, IA 51501

SpringHill Suites by Marriott Omaha East/Council Bluffs, IA

3216 Plaza View Dr, Council Bluffs, IA 51501

PHOTO DISCLOSURE

Photos and video will be taken at the event that may be used for marketing purposes.

PLANT SAFETY

Safety glasses (provided) and closed toe shoes are required for all plant tours.