Driving Excellence in Food and Beverage Automation

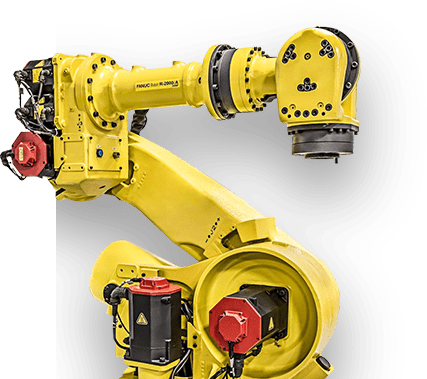

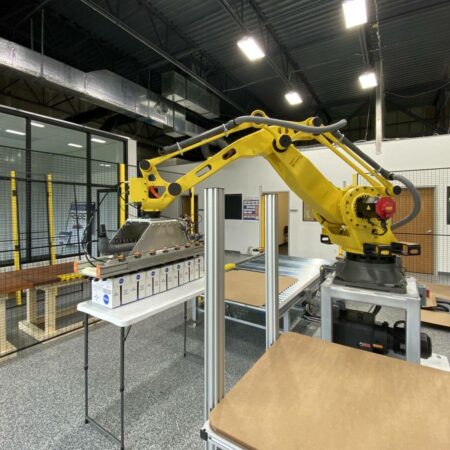

As a FANUC Authorized System Integrator (ASI) and A3 Certified Robot Integrator, Acieta specializes in designing and integrating a full range of robotic palletizing systems tailored to meet the unique challenges of the food and beverage industry.

Our history of successful project implementations makes us a reliable partner. We have played a pivotal role in enhancing food and beverage packaging automation for clients globally. Our goal is to ensure that your operations run smoothly while meeting the highest industry standards.