Need to Improve productivity and capacity, fast? Manufacturers who are positioning for growth are planning for automation. The challenge with adopting complex, custom solutions lies in the time and capital investment required for custom integrations. If you’re faced with capacity challenges, labor shortages or quality variability, the standard cell choices from Acieta will help you address key business challenges, fast, with a high-speed machine loading cell.

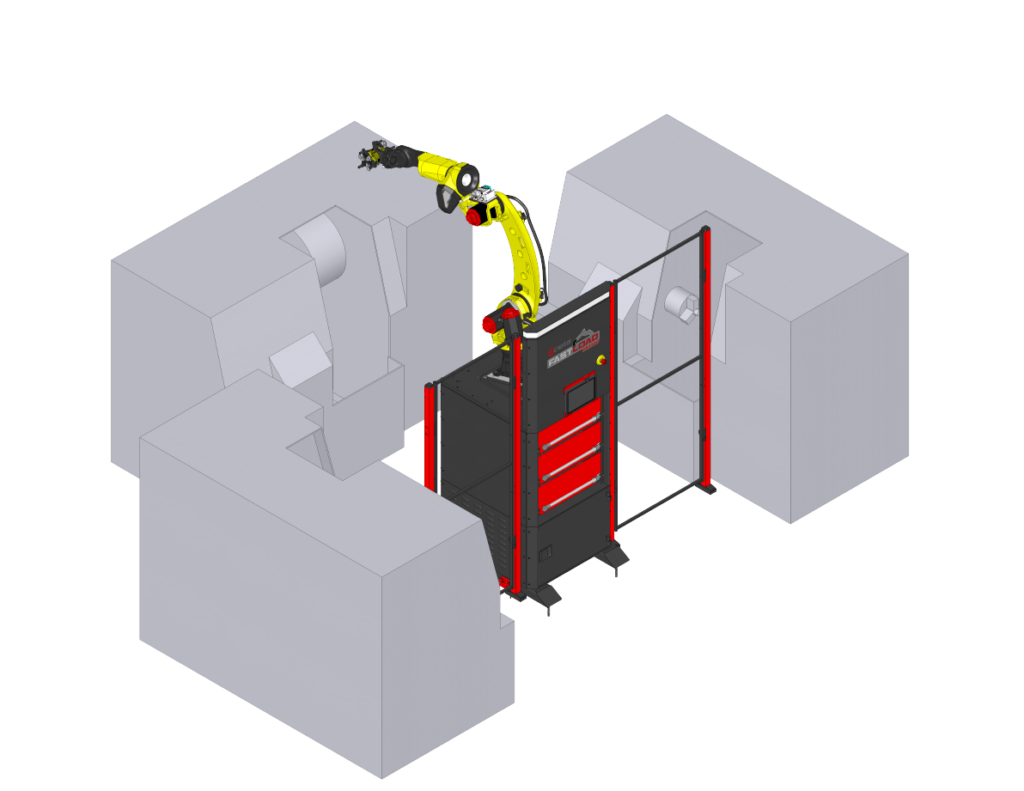

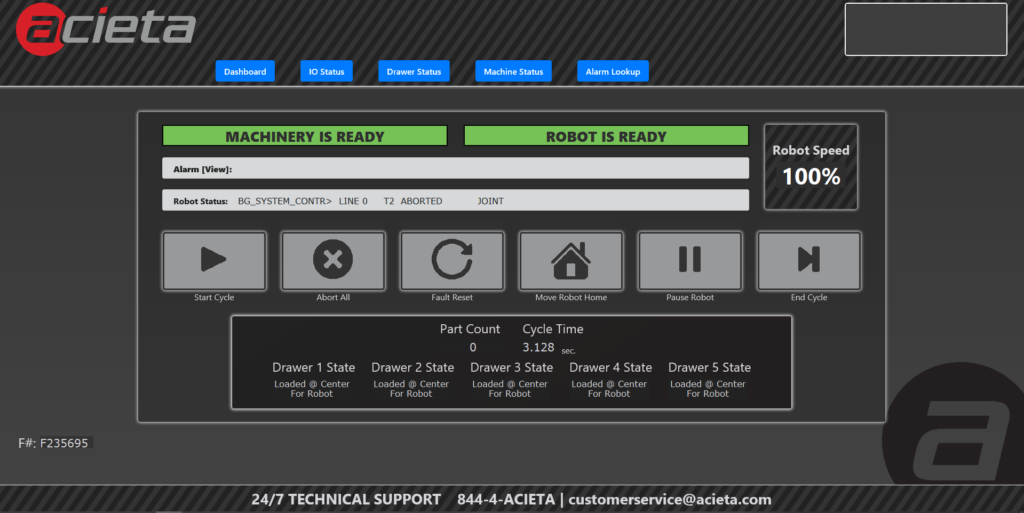

Our FastLOAD® DR2000 automation machine tool cell is an excellent option for companies looking to maximize efficiency with automation.

- Address core business challenges, fast

- Low commitment, fast entry to automation

- Easily customizable for a wide variety of applications

- High-speed machine tool cells can tend multiple machines

- Small footprint

- Fast lead time