Acieta, Mid-State Engineering, RoBEX and +Vantage have united to transform your operations. INNOVATE to get ahead, INTEGRATE for seamless efficiency, and DOMINATE your market. With us, you're not just prepared for the future; you are forging it. Visit acieta.com/edge for more information.

Videos

Acieta – A POWERHOUSE OF EXPERTISE

Acieta, Mid-State Engineering, RoBEX and +Vantage have united to transform your operations. INNOVATE to get ahead, INTEGRATE for seamless efficiency, and DOMINATE your market. With us, you're not just prepared for the future; you are forging it. Visit acieta.com/edge for more information.

Read More

Acieta, Mid-State Engineering, RoBEX and +Vantage have united to transform your operations. INNOVATE to get ahead, INTEGRATE for seamless efficiency, and DOMINATE your market. With us, you're not just prepared for the future; you are forging it. Visit acieta.com/edge for more information.

Listen, Adapt, Succeed: Navigating Customer Concerns in the Age of Automation

Tony Gunn from MTDCNC and Jonathan Darling from Acieta explore the crucial role of addressing customer concerns in the rapidly evolving world of automation. Discover why manufacturers often hesitate to automate and how listening to customer feedback can turn uncertainty into a competitive advantage. Learn strategies to transform negative feedback into opportunities for growth, ensuring that automation technologies truly meet customer needs and expectations. Tune in to gain valuable insights on enhancing customer satisfaction and driving business success through effective communication and adaptation.

Read More

Tony Gunn from MTDCNC and Jonathan Darling from Acieta explore the crucial role of addressing customer concerns in the rapidly evolving world of automation. Discover why manufacturers often hesitate to automate and how listening to customer feedback can turn uncertainty into a competitive advantage. Learn strategies to transform negative feedback into opportunities for growth, ensuring that automation technologies truly meet customer needs and expectations. Tune in to gain valuable insights on enhancing customer satisfaction and driving business success through effective communication and adaptation.

Tony Gunn from MTDCNC and Jonathan Darling from Acieta explore the crucial role of addressing customer concerns in the rapidly evolving world of automation. Discover why manufacturers often hesitate to automate and how listening to customer feedback can turn uncertainty into a competitive advantage. Learn strategies to transform negative feedback into opportunities for growth, ensuring that automation technologies truly meet customer needs and expectations. Tune in to gain valuable insights on enhancing customer satisfaction and driving business success through effective communication and adaptation.

FastGAUGE: Redefining Precision for Manufacturers

In today's manufacturing landscape, the quest for enhanced precision and efficiency is crucial to staying competitive. The new FastGAUGE Precision Metrology Solution, coupled with the innovative FastLOAD CX2000, is set to transform quality control processes across the manufacturing industry. FastGAUGE directly addresses common shop floor challenges, including time-consuming manual inspections, inconsistent quality, and the high costs associated with errors. Discover how FastGAUGE streamlines operations, transforming quality control from a mere checkpoint to a catalyst for excellence. FastGAUGE is not merely about inspection—it's about setting a new standard in manufacturing innovation.

Read More

In today's manufacturing landscape, the quest for enhanced precision and efficiency is crucial to staying competitive. The new FastGAUGE Precision Metrology Solution, coupled with the innovative FastLOAD CX2000, is set to transform quality control processes across the manufacturing industry. FastGAUGE directly addresses common shop floor challenges, including time-consuming manual inspections, inconsistent quality, and the high costs associated with errors. Discover how FastGAUGE streamlines operations, transforming quality control from a mere checkpoint to a catalyst for excellence. FastGAUGE is not merely about inspection—it's about setting a new standard in manufacturing innovation.

In today's manufacturing landscape, the quest for enhanced precision and efficiency is crucial to staying competitive. The new FastGAUGE Precision Metrology Solution, coupled with the innovative FastLOAD CX2000, is set to transform quality control processes across the manufacturing industry. FastGAUGE directly addresses common shop floor challenges, including time-consuming manual inspections, inconsistent quality, and the high costs associated with errors. Discover how FastGAUGE streamlines operations, transforming quality control from a mere checkpoint to a catalyst for excellence. FastGAUGE is not merely about inspection—it's about setting a new standard in manufacturing innovation.

Transforming Hydraulic Cylinder Manufacturing: The FastARC PW Robotic Port Welder

In the competitive field of hydraulic cylinder manufacturing, the FastARC Port Welder (PW) by Acieta stands out as a tailored solution designed to enhance quality, reduce costs, and ensure timely production. Equipped with a FANUC 6-axis robot and versatile end-of-arm tooling, this system delivers automated precision and efficiency. Compatible with top welding brands and engineered for quick setup and straightforward operation, the FastARC PW not only accelerates production but also maintains accuracy in port placement—significantly minimizing scrap and rework. Watch this video featuring John Burg to see how the FastARC PW can transform your manufacturing process.

Read More

In the competitive field of hydraulic cylinder manufacturing, the FastARC Port Welder (PW) by Acieta stands out as a tailored solution designed to enhance quality, reduce costs, and ensure timely production. Equipped with a FANUC 6-axis robot and versatile end-of-arm tooling, this system delivers automated precision and efficiency. Compatible with top welding brands and engineered for quick setup and straightforward operation, the FastARC PW not only accelerates production but also maintains accuracy in port placement—significantly minimizing scrap and rework. Watch this video featuring John Burg to see how the FastARC PW can transform your manufacturing process.

In the competitive field of hydraulic cylinder manufacturing, the FastARC Port Welder (PW) by Acieta stands out as a tailored solution designed to enhance quality, reduce costs, and ensure timely production. Equipped with a FANUC 6-axis robot and versatile end-of-arm tooling, this system delivers automated precision and efficiency. Compatible with top welding brands and engineered for quick setup and straightforward operation, the FastARC PW not only accelerates production but also maintains accuracy in port placement—significantly minimizing scrap and rework. Watch this video featuring John Burg to see how the FastARC PW can transform your manufacturing process.

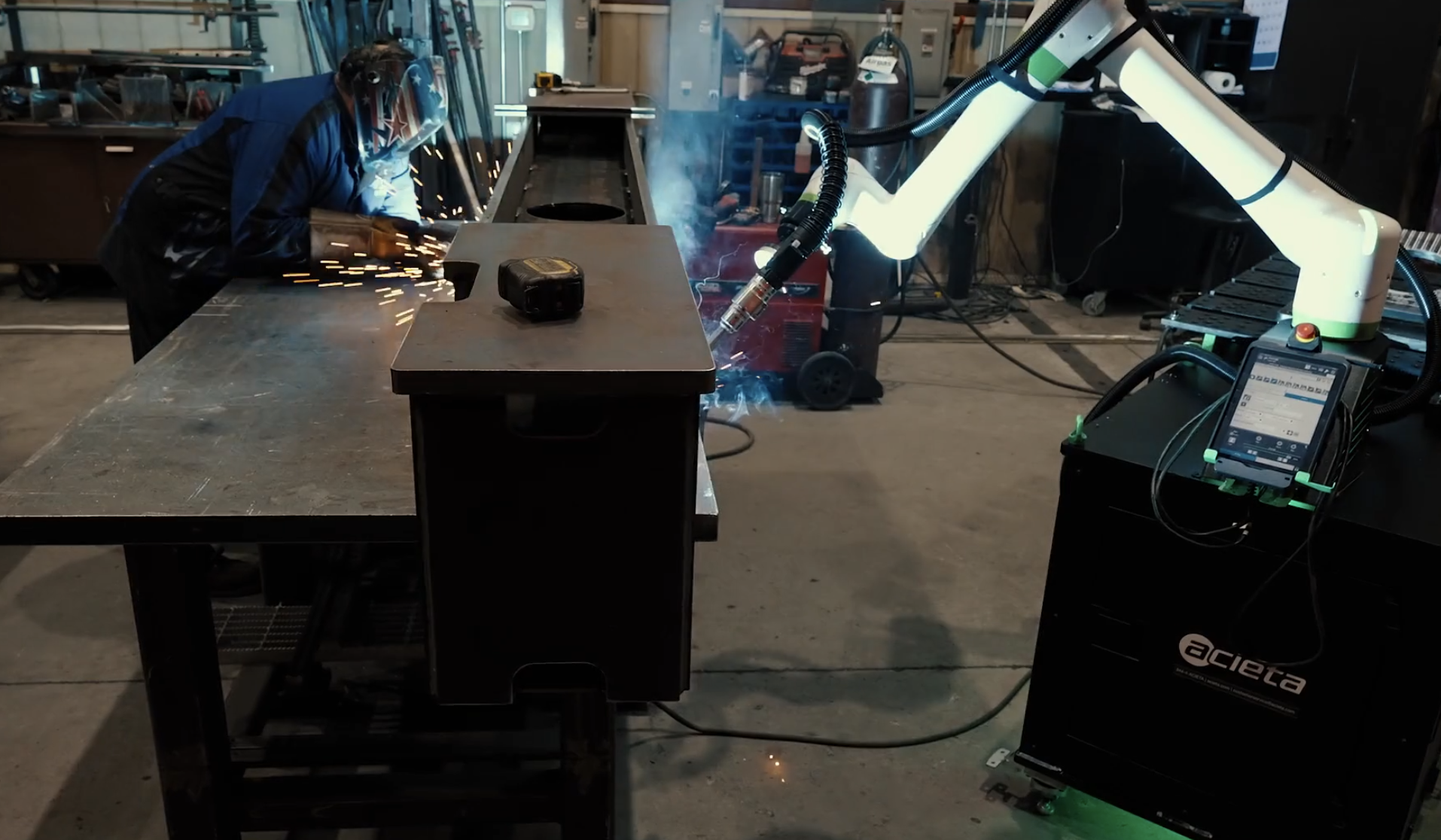

Joint Efforts = Great Welds

At Acieta, we're proud to highlight our partnership with United Alloy, a premier fabricator renowned for their leak-proof vessels. This collaboration focused on integrating robotics into their production line, a move that has significantly enhanced output to meet and exceed the growing demands of their customers. Our joint effort underscores the importance of teamwork and the adaptability provided by advanced technology. It's a testament to the value of choosing the right integrator, one with deep industry experience and a commitment to excellence, and serves as a shining example of how strategic collaboration and technological innovation can drive market expansion and dramatically improve return on investment (ROI). 'Joint Efforts = Great Welds' is not just about achieving immediate goals but about setting a course for sustained growth and the continual pursuit of perfection.

Read More

At Acieta, we're proud to highlight our partnership with United Alloy, a premier fabricator renowned for their leak-proof vessels. This collaboration focused on integrating robotics into their production line, a move that has significantly enhanced output to meet and exceed the growing demands of their customers. Our joint effort underscores the importance of teamwork and the adaptability provided by advanced technology. It's a testament to the value of choosing the right integrator, one with deep industry experience and a commitment to excellence, and serves as a shining example of how strategic collaboration and technological innovation can drive market expansion and dramatically improve return on investment (ROI). 'Joint Efforts = Great Welds' is not just about achieving immediate goals but about setting a course for sustained growth and the continual pursuit of perfection.

At Acieta, we're proud to highlight our partnership with United Alloy, a premier fabricator renowned for their leak-proof vessels. This collaboration focused on integrating robotics into their production line, a move that has significantly enhanced output to meet and exceed the growing demands of their customers. Our joint effort underscores the importance of teamwork and the adaptability provided by advanced technology. It's a testament to the value of choosing the right integrator, one with deep industry experience and a commitment to excellence, and serves as a shining example of how strategic collaboration and technological innovation can drive market expansion and dramatically improve return on investment (ROI). 'Joint Efforts = Great Welds' is not just about achieving immediate goals but about setting a course for sustained growth and the continual pursuit of perfection.

Collaborative Innovation Technology

This collaboration underscores Acieta's dedicated commitment to closely partnering with our customers, meeting them precisely where they are in their technological journey. As United Alloy conducts its own programming on our shop floor, this unique approach not only expedites the implementation process but also equips the United Alloy team with invaluable knowledge and experience gained through direct involvement. Together, we seamlessly blend our expertise to push the boundaries of robotic automation. True collaboration emerges as innovation is fueled by our joint efforts, from conceptualization to execution.

Read More

This collaboration underscores Acieta's dedicated commitment to closely partnering with our customers, meeting them precisely where they are in their technological journey. As United Alloy conducts its own programming on our shop floor, this unique approach not only expedites the implementation process but also equips the United Alloy team with invaluable knowledge and experience gained through direct involvement. Together, we seamlessly blend our expertise to push the boundaries of robotic automation. True collaboration emerges as innovation is fueled by our joint efforts, from conceptualization to execution.

This collaboration underscores Acieta's dedicated commitment to closely partnering with our customers, meeting them precisely where they are in their technological journey. As United Alloy conducts its own programming on our shop floor, this unique approach not only expedites the implementation process but also equips the United Alloy team with invaluable knowledge and experience gained through direct involvement. Together, we seamlessly blend our expertise to push the boundaries of robotic automation. True collaboration emerges as innovation is fueled by our joint efforts, from conceptualization to execution.

Shaping Futures: Saratoga STEM Students Explore Acieta

Dive into the world of manufacturing and robotics with the Saratoga STEM Academy's engaging tour at Acieta. This educational video spotlights middle school students as they interact with cutting-edge robotics, guided by Acieta’s experts. Through interviews and hands-on experiences, we highlight the critical role of STEM education in closing the skills gap and opening up exciting career possibilities. Join us in nurturing the innovators of tomorrow and illustrating the power of early STEM education to meet future technological challenges. "Inspire locally, impact globally" with Acieta. Let's inspire the next generation to dream big, innovate, and make a significant global impact.

Read More

Dive into the world of manufacturing and robotics with the Saratoga STEM Academy's engaging tour at Acieta. This educational video spotlights middle school students as they interact with cutting-edge robotics, guided by Acieta’s experts. Through interviews and hands-on experiences, we highlight the critical role of STEM education in closing the skills gap and opening up exciting career possibilities. Join us in nurturing the innovators of tomorrow and illustrating the power of early STEM education to meet future technological challenges. "Inspire locally, impact globally" with Acieta. Let's inspire the next generation to dream big, innovate, and make a significant global impact.

Dive into the world of manufacturing and robotics with the Saratoga STEM Academy's engaging tour at Acieta. This educational video spotlights middle school students as they interact with cutting-edge robotics, guided by Acieta’s experts. Through interviews and hands-on experiences, we highlight the critical role of STEM education in closing the skills gap and opening up exciting career possibilities. Join us in nurturing the innovators of tomorrow and illustrating the power of early STEM education to meet future technological challenges. "Inspire locally, impact globally" with Acieta. Let's inspire the next generation to dream big, innovate, and make a significant global impact.

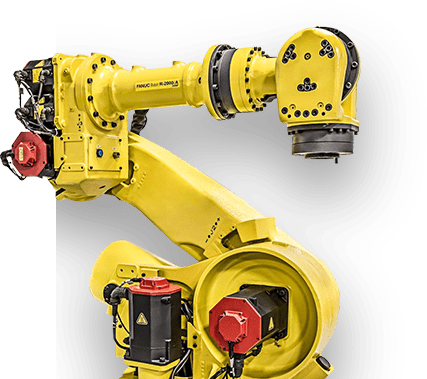

Innovation Meets Efficiency

In this video, Acieta's robotic press brake solution (RIBS), utilizing a FANUC M900 robot, expertly handles the tending and stacking of large, heavy metal parts with unparalleled ease. This robotic marvel not only alleviates the physical strain on operators by eliminating the need for manual lifting but also significantly enhances the quality consistency of the products. Each metal piece is manipulated with exact precision, showcasing a leap forward in manufacturing efficiency and worker safety. This brief video illustrates the profound impact of robotics on improving both the ergonomic well-being of operators and the overall quality of production.

Read More

In this video, Acieta's robotic press brake solution (RIBS), utilizing a FANUC M900 robot, expertly handles the tending and stacking of large, heavy metal parts with unparalleled ease. This robotic marvel not only alleviates the physical strain on operators by eliminating the need for manual lifting but also significantly enhances the quality consistency of the products. Each metal piece is manipulated with exact precision, showcasing a leap forward in manufacturing efficiency and worker safety. This brief video illustrates the profound impact of robotics on improving both the ergonomic well-being of operators and the overall quality of production.

In this video, Acieta's robotic press brake solution (RIBS), utilizing a FANUC M900 robot, expertly handles the tending and stacking of large, heavy metal parts with unparalleled ease. This robotic marvel not only alleviates the physical strain on operators by eliminating the need for manual lifting but also significantly enhances the quality consistency of the products. Each metal piece is manipulated with exact precision, showcasing a leap forward in manufacturing efficiency and worker safety. This brief video illustrates the profound impact of robotics on improving both the ergonomic well-being of operators and the overall quality of production.

Code, Create, Conquer: Nurturing Future Innovators at Acieta

In an inspiring journey of discovery and empowerment, a local Girl Scout troop ventured into the heart of Acieta, with a mission to earn their Robotics Programming Badge. Through hands-on learning and real-world application, they explore the endless possibilities of technology, igniting a spark of curiosity and determination. "Code, Create, Conquer" is more than just a story of earning a badge; it's a testament to the impact we can achieve when we are dedicated to engaging and educating young minds, demonstrating the power of community and technology coming together. Join us as we inspire locally to impact globally, building tomorrow together.

Read More

In an inspiring journey of discovery and empowerment, a local Girl Scout troop ventured into the heart of Acieta, with a mission to earn their Robotics Programming Badge. Through hands-on learning and real-world application, they explore the endless possibilities of technology, igniting a spark of curiosity and determination. "Code, Create, Conquer" is more than just a story of earning a badge; it's a testament to the impact we can achieve when we are dedicated to engaging and educating young minds, demonstrating the power of community and technology coming together. Join us as we inspire locally to impact globally, building tomorrow together.

In an inspiring journey of discovery and empowerment, a local Girl Scout troop ventured into the heart of Acieta, with a mission to earn their Robotics Programming Badge. Through hands-on learning and real-world application, they explore the endless possibilities of technology, igniting a spark of curiosity and determination. "Code, Create, Conquer" is more than just a story of earning a badge; it's a testament to the impact we can achieve when we are dedicated to engaging and educating young minds, demonstrating the power of community and technology coming together. Join us as we inspire locally to impact globally, building tomorrow together.

Spreading Holiday Cheer: Acieta’s Heartwarming Volunteer Event at New Visions

Join us on a heartwarming journey as Acieta employees unite to illuminate the holiday season at New Visions. Explore the essence of New Visions and its profound impact on the community. Listen to some of our dedicated teammates as they share why community service lies at the very core of Acieta's values. Together, let's celebrate the joy of giving and our unwavering commitment to our community.

Read More

Join us on a heartwarming journey as Acieta employees unite to illuminate the holiday season at New Visions. Explore the essence of New Visions and its profound impact on the community. Listen to some of our dedicated teammates as they share why community service lies at the very core of Acieta's values. Together, let's celebrate the joy of giving and our unwavering commitment to our community.

Join us on a heartwarming journey as Acieta employees unite to illuminate the holiday season at New Visions. Explore the essence of New Visions and its profound impact on the community. Listen to some of our dedicated teammates as they share why community service lies at the very core of Acieta's values. Together, let's celebrate the joy of giving and our unwavering commitment to our community.

Creating a Weld Procedure on the FastARC CW – Step-by-Step Guide

In this step-by-step video tutorial, we’ll guide you through the process of creating a weld procedure on our FastARC CW with the FANUC CRX-10iA robot. Whether you’re a beginner or an experienced welder, this video will help you set up a welding procedure efficiently.

Read More

In this step-by-step video tutorial, we’ll guide you through the process of creating a weld procedure on our FastARC CW with the FANUC CRX-10iA robot. Whether you’re a beginner or an experienced welder, this video will help you set up a welding procedure efficiently.

In this step-by-step video tutorial, we’ll guide you through the process of creating a weld procedure on our FastARC CW with the FANUC CRX-10iA robot. Whether you’re a beginner or an experienced welder, this video will help you set up a welding procedure efficiently.

Creating a Weave Schedule on the FastARC CW – Step-by-Step Guide

In this step-by-step video tutorial, we’ll guide you through the process of creating a weave schedule on our FastARC CW with the FANUC CRX-10iA robot. Whether you’re a beginner or an experienced welder, this video will help show you how to set up a weave schedule.

Read More

In this step-by-step video tutorial, we’ll guide you through the process of creating a weave schedule on our FastARC CW with the FANUC CRX-10iA robot. Whether you’re a beginner or an experienced welder, this video will help show you how to set up a weave schedule.

In this step-by-step video tutorial, we’ll guide you through the process of creating a weave schedule on our FastARC CW with the FANUC CRX-10iA robot. Whether you’re a beginner or an experienced welder, this video will help show you how to set up a weave schedule.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: