Despite the many benefits of robotic automation solutions, several manufacturers are still reluctant to take the leap and invest in a system for their business. We’re here to dispel the misunderstandings around robots and help manufacturers of all sizes invest in the tools that will help their businesses thrive.

Myths

Myth 1: Robots Are Expensive

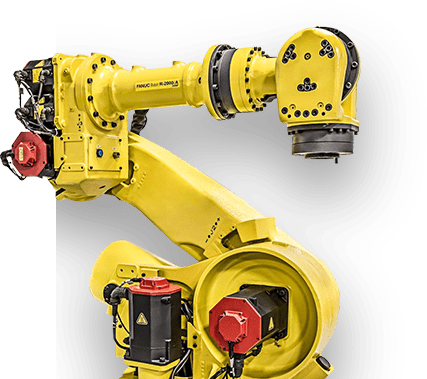

State-of-the-art factories produce robots in quantity, resulting in low prices and high quality. Robotic automation is a lower-risk investment than dedicated equipment. If demand changes or new products are introduced a robot can be redeployed quickly. It’s clear to see that robotic automation is an affordable option, even for small manufacturers.

Myth 2: Robots Are Only For High-Volume Operations

Modern robots can be used effectively in low- to medium-volume manufacturing. They are programmed and changed over quickly, resulting in economical high-speed. This allows your robots to be able to address a task that needs to be consistently performed or move around as operational needs change.

Myth 3: Robots Are Hard To Program

A robot is programmed via a teach pendant or through an offline PC program. Offline programming allows a user to model a complete cell and develop the sequence of moves that the robot will use without stopping production to create. Only when the programmer is satisfied with the taught motion will he run it at 100 percent, saving time and headache.

Myth 4: Robots Systems Are Complicated And Difficult To Support

Robots are very reliable machines. Vendors quote mean time between failure (MTBF) numbers of 62,000 hours or more, (about seven years). A robot cell typically includes other equipment plus numerous sensors that may have lower reliability, but overall a cell is usually less complex than dedicated automated equipment.

The Biggest Myth of All?

It’s sometimes said that robots eliminate jobs.

Robots shift jobs. Robots take on the menial, dirty, repetitive undesirable work that human operators do not want to do. In turn, with the increased productivity of automation, manufacturers have shorter lead times, lower part cost, less scrap, more consistent parts, which ultimately leads to winning more business….and more business leads to more jobs created.

How Robots Create Jobs

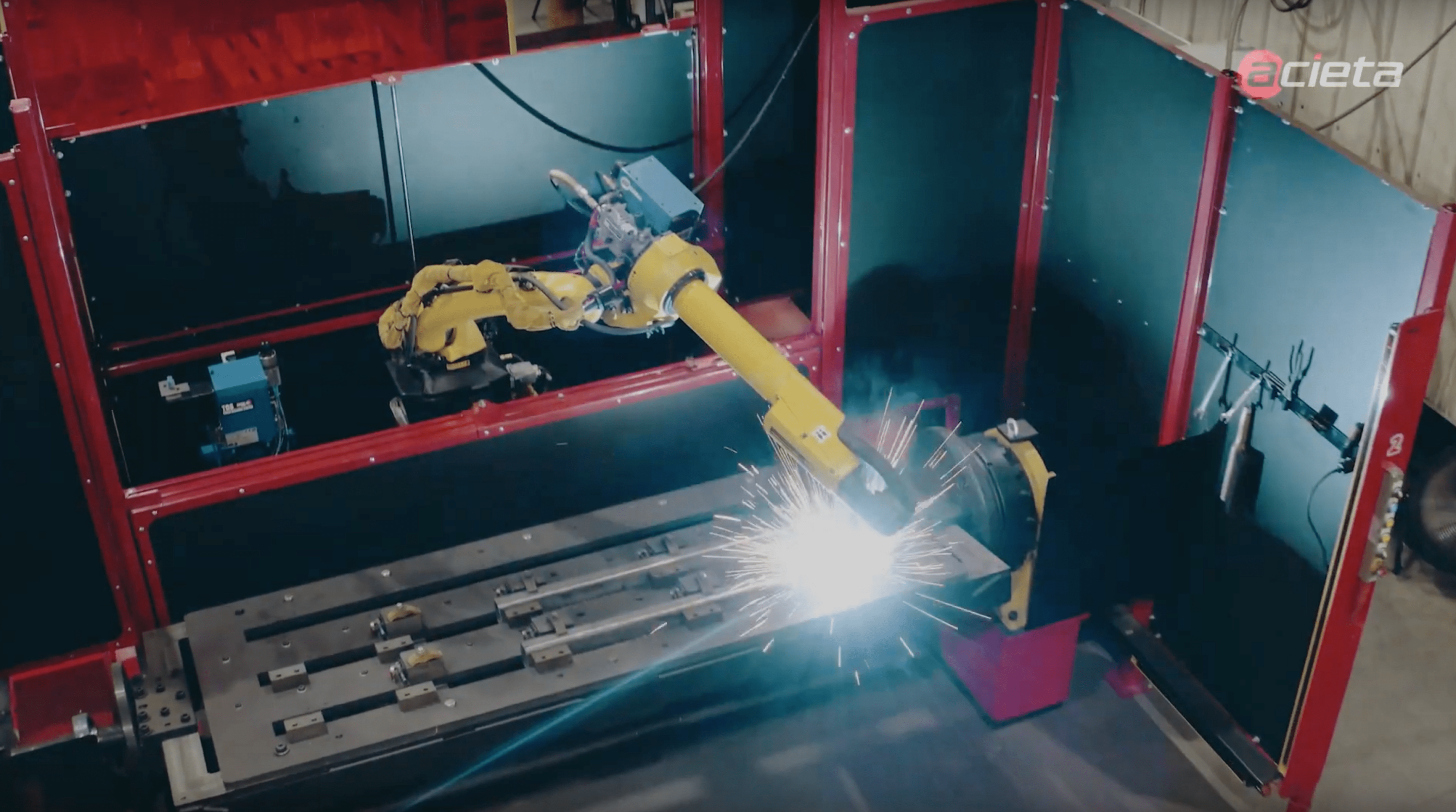

There are some jobs that robots do better than people — anything requiring repetitive motion, consistency, speed and precision. In fact, some miniaturized products can only be assembled by robots. Higher quality and increased productivity lowers costs, which stimulates demand that benefits everyone.

There are some jobs that robots do better than people — anything requiring repetitive motion, consistency, speed and precision. In fact, some miniaturized products can only be assembled by robots. Higher quality and increased productivity lowers costs, which stimulates demand that benefits everyone.

More specifically, jobs are created directly in robot and associated industries, in fields like programming, engineering, end-effector design and manufacture, and integration. Other jobs are created as manufacturing businesses grow, as well as more opportunities from onshoring as lower costs let manufacturers bring work back to U.S. soil.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: