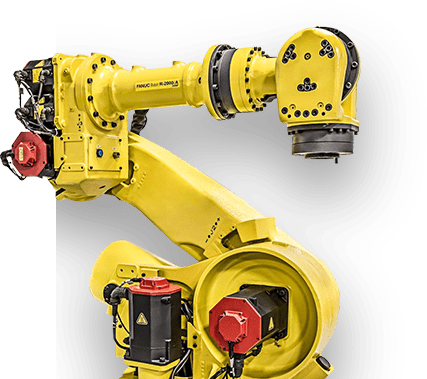

Implementing robotics in electronics manufacturing takes extensive automation experience and a deep understanding of the industry’s unique challenges. Small parts, high speeds, precise placement. Human assembly, dispensing and inspection just aren’t feasible at the rate demanded by modern production operations, and electronic components are too miniaturized for human assembly.

Robotics In The Electronics Industry

Acieta’s robotic solutions for automation in electronics provide the flexibility to switch quickly between product variants. If demand shifts suddenly, robotic technology is more easily reconfigured. Every cycle is performed the same way, so each electronic manufacturing process is identical. That means better quality, higher yields and potentially fewer customer returns.

Deploying robots in electronic manufacturing also protects workers from jobs that are potentially dangerous. Twisting and lifting in handling, packaging and particularly palletizing tasks can have hazardous effects. Solvents in sealing materials and adhesives may also have health implications, a robot avoids this risk.

Electronics Robotics Applications

Intense cost pressures push manufacturers to process, assemble and pack faster than ever while simultaneously maximizing yields. Acieta understands the special challenges of this sector and offers electronics manufacturing automation to suit these needs. Here are some of the best-suited application areas:

- CHALLENGING APPLICATIONS – Robots can handle display screens, assemble connectors, build subassemblies and populate and coat circuit boards. They can apply adhesives and sealants, perform inspections, test operations, pack and palletize finished products and perform a variety of other challenging applications

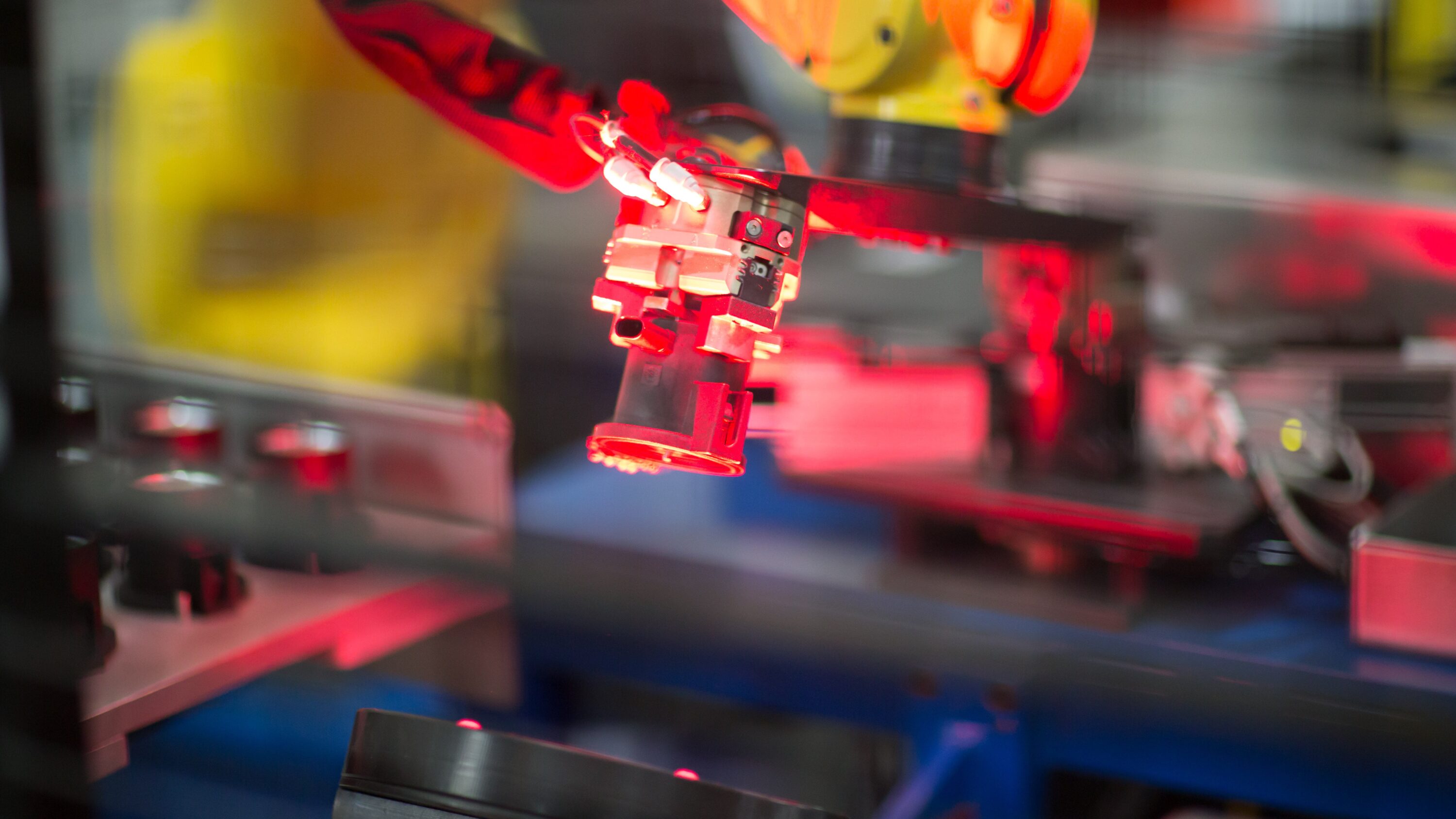

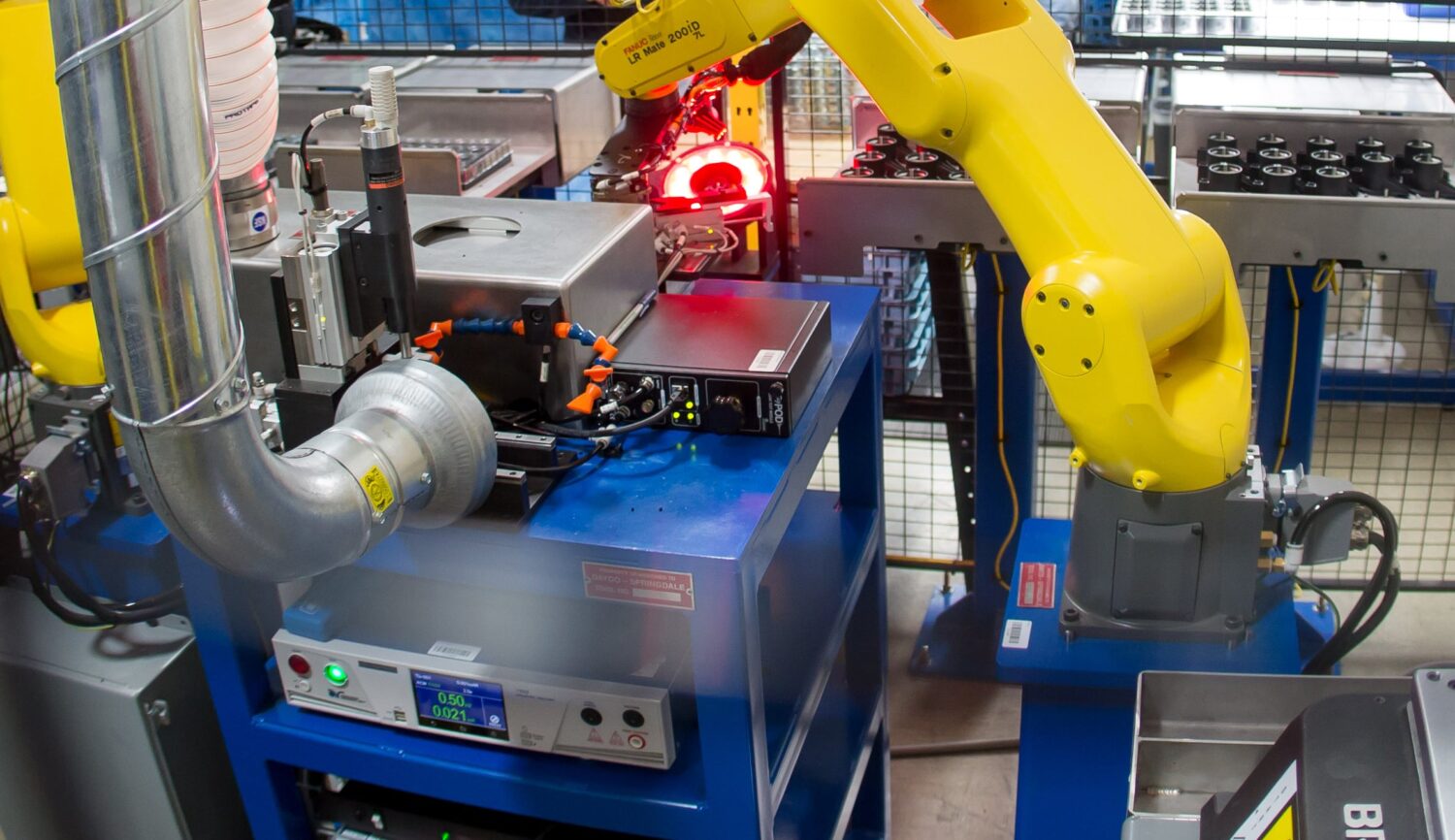

- ASSEMBLY – Component placement tasks are a good electronics assembly automation application. Accommodating part-to-part variation (especially important with circuit board features) means vision and force sensing are essential in electronic assembly. High-resolution cameras locate features within a few thousandths of an inch and supply offsets to robots on the fly. Force sensing allows for parts to be finessed into place. When coupled with flexible part feeders and vision systems, robots add versatility to automated electronics assembly systems.

- INSPECTION AND FUNCTIONAL TESTING – Arm-mounted cameras can verify correct assembly or solder joint quality or read unique identification codes for product traceability. When a circuit board is turned on, an IR camera can look for hot spots signaling possible premature failure. Touch-screen functional testing is another good robot application, with the machine applying consistent pressure for exactly the same duration on every cycle.

- PACKING – Robots in the electronics industry can kit and pack assemble products at high speed. Individual packages are packed into cartons robotically and the cartons are palletized – all without human intervention.

- DISPENSING – Electronic products often need sealants and selectively applied coatings for protection against environmental degradation, vibration and temperature. In assembly, adhesives are sometimes used to secure components, housings or screens. When a robot does the dispensing, waste is minimal and part-to-part repeatability is high.

- MINIATURIZATION – Some jobs, especially electronic assembly work, are just not possible for humans to do because the components are too small, and their placement needs are too precise. In parallel, product engineers increasingly understand what robotic technology can do and are designing for it.

Whether you’re in electronics manufacturing or another industry, Acieta’s robotic automation solutions can help your business, identify opportunities and support you through every step of your project. Get started by contacting us today.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: