Now’s the time to invest in automation to increase productivity, streamline processes, and improve worker safety. Schedule a virtual meeting with Acieta today to start your automation project.

Videos

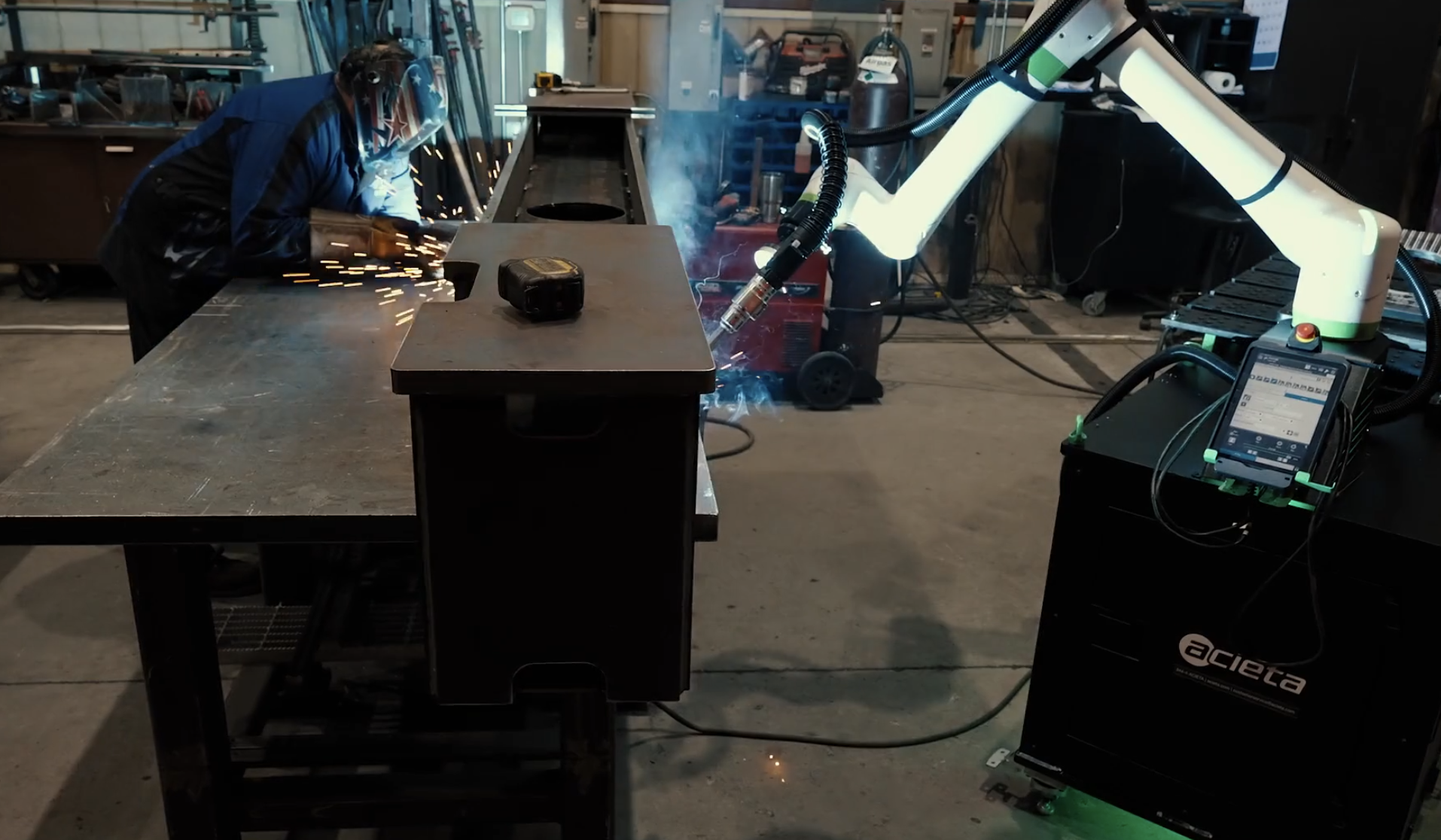

Intuitive Drilling with Acieta

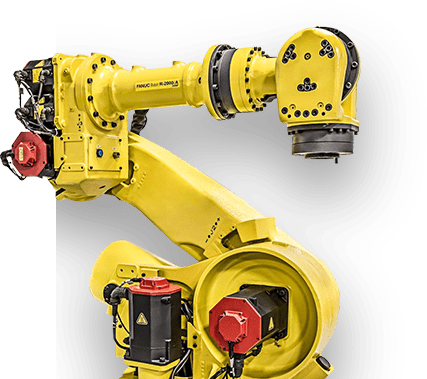

What was at first a dangerous operation, Acieta’s robotic solution amplified this drilling process. This customer is able to fully customize and adjust their FANUC robot capabilities on nearly any desired drillable material. Additionally, this new process streamlines what used to require numerous man hours for repositioning and loading materials alone. Our premier robotic integration solutions allow your business to mitigate the grunt work, freeing workers for more creative endeavors and sparing them the strain on their bodies. Acieta’s solutions alleviate scrap waste and manual labor while boosting the consistency of your products. With guaranteed accuracy, capability, and repeatability, the result brings significant ROI. If you are currently using a crane to lift and rotate materials due to sheer weight, stop putting your team at risk and contact us today.

Read More

What was at first a dangerous operation, Acieta’s robotic solution amplified this drilling process. This customer is able to fully customize and adjust their FANUC robot capabilities on nearly any desired drillable material. Additionally, this new process streamlines what used to require numerous man hours for repositioning and loading materials alone. Our premier robotic integration solutions allow your business to mitigate the grunt work, freeing workers for more creative endeavors and sparing them the strain on their bodies. Acieta’s solutions alleviate scrap waste and manual labor while boosting the consistency of your products. With guaranteed accuracy, capability, and repeatability, the result brings significant ROI. If you are currently using a crane to lift and rotate materials due to sheer weight, stop putting your team at risk and contact us today.

What was at first a dangerous operation, Acieta’s robotic solution amplified this drilling process. This customer is able to fully customize and adjust their FANUC robot capabilities on nearly any desired drillable material. Additionally, this new process streamlines what used to require numerous man hours for repositioning and loading materials alone. Our premier robotic integration solutions allow your business to mitigate the grunt work, freeing workers for more creative endeavors and sparing them the strain on their bodies. Acieta’s solutions alleviate scrap waste and manual labor while boosting the consistency of your products. With guaranteed accuracy, capability, and repeatability, the result brings significant ROI. If you are currently using a crane to lift and rotate materials due to sheer weight, stop putting your team at risk and contact us today.

Climbing the Ladder with Robotics

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a higher ROI for the company. See this innovative robotic system in action.

Read More

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a higher ROI for the company. See this innovative robotic system in action.

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a higher ROI for the company. See this innovative robotic system in action.

Acieta is Here to Keep You Up and Running Now and in the Future.

Robotic automation solutions not only help save floor space, increase productivity, and improve plant efficiency, they are also fundamental in creating peace of mind during uncertain times. Acieta’s robotic solutions help manage the turbulence of the unexpected. Contact us for a virtual visit, phone, or in person meeting today.

Read More

Robotic automation solutions not only help save floor space, increase productivity, and improve plant efficiency, they are also fundamental in creating peace of mind during uncertain times. Acieta’s robotic solutions help manage the turbulence of the unexpected. Contact us for a virtual visit, phone, or in person meeting today.

Robotic automation solutions not only help save floor space, increase productivity, and improve plant efficiency, they are also fundamental in creating peace of mind during uncertain times. Acieta’s robotic solutions help manage the turbulence of the unexpected. Contact us for a virtual visit, phone, or in person meeting today.

Address Labor and Capacity Challenges with the Acieta FastLOAD® CR2000

If you’re faced with capacity challenges, labor shortages, or quality variability, FastLOAD CR2000 by Acieta can help you address key business challenges, fast, with a collaborative machine loading cell. Our FastLOAD CR2000 is an excellent option for companies looking to maximize efficiency with automation. Address core business challenges, fast. Low commitment, fast entry to automation. Move to custom solutions, faster. Fast lead time.

Read More

If you’re faced with capacity challenges, labor shortages, or quality variability, FastLOAD CR2000 by Acieta can help you address key business challenges, fast, with a collaborative machine loading cell. Our FastLOAD CR2000 is an excellent option for companies looking to maximize efficiency with automation. Address core business challenges, fast. Low commitment, fast entry to automation. Move to custom solutions, faster. Fast lead time.

If you’re faced with capacity challenges, labor shortages, or quality variability, FastLOAD CR2000 by Acieta can help you address key business challenges, fast, with a collaborative machine loading cell. Our FastLOAD CR2000 is an excellent option for companies looking to maximize efficiency with automation. Address core business challenges, fast. Low commitment, fast entry to automation. Move to custom solutions, faster. Fast lead time.

Acieta FastLOAD CR2000: Augment Your Operations

If you’re faced with capacity challenges, labor shortages, or quality variability, FastLOAD CR2000 by Acieta can help you address key business challenges, fast, with a collaborative machine loading cell. Our FastLOAD CR2000 is an excellent option for companies looking to maximize efficiency with automation. Address core business challenges, fast. Low commitment, fast entry to automation. Move to custom solutions, faster. Fast lead time.

Read More

If you’re faced with capacity challenges, labor shortages, or quality variability, FastLOAD CR2000 by Acieta can help you address key business challenges, fast, with a collaborative machine loading cell. Our FastLOAD CR2000 is an excellent option for companies looking to maximize efficiency with automation. Address core business challenges, fast. Low commitment, fast entry to automation. Move to custom solutions, faster. Fast lead time.

If you’re faced with capacity challenges, labor shortages, or quality variability, FastLOAD CR2000 by Acieta can help you address key business challenges, fast, with a collaborative machine loading cell. Our FastLOAD CR2000 is an excellent option for companies looking to maximize efficiency with automation. Address core business challenges, fast. Low commitment, fast entry to automation. Move to custom solutions, faster. Fast lead time.

Do More With Less

Improve power in all sectors with one cohesive solution. Acieta automation solutions, customized for your company needs. - Increase productivity for customer demand - Bolster labor gaps and help your staff - Reduce floor space - Reduce lead time At Acieta, we understand there's more to automating a process than simply adding industrial robots. success depends on building a strong partnership that doesn't end when the cell is powered up. During our consultation, it is our goal to uncover the best solution for your business growth. With over 35 years of robotic integration experience, and the backing of both FANUC and RIA certifications, our team are the automation experts you can trust. Boost your success today, let's start a dialogue.

Read More

Improve power in all sectors with one cohesive solution. Acieta automation solutions, customized for your company needs. - Increase productivity for customer demand - Bolster labor gaps and help your staff - Reduce floor space - Reduce lead time At Acieta, we understand there's more to automating a process than simply adding industrial robots. success depends on building a strong partnership that doesn't end when the cell is powered up. During our consultation, it is our goal to uncover the best solution for your business growth. With over 35 years of robotic integration experience, and the backing of both FANUC and RIA certifications, our team are the automation experts you can trust. Boost your success today, let's start a dialogue.

Improve power in all sectors with one cohesive solution. Acieta automation solutions, customized for your company needs. - Increase productivity for customer demand - Bolster labor gaps and help your staff - Reduce floor space - Reduce lead time At Acieta, we understand there's more to automating a process than simply adding industrial robots. success depends on building a strong partnership that doesn't end when the cell is powered up. During our consultation, it is our goal to uncover the best solution for your business growth. With over 35 years of robotic integration experience, and the backing of both FANUC and RIA certifications, our team are the automation experts you can trust. Boost your success today, let's start a dialogue.

Robots Bend, Weld and Palletize for Metal Fabricator

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a XX ROI for the company. See this innovative robotic system in action.

Read More

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a XX ROI for the company. See this innovative robotic system in action.

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a XX ROI for the company. See this innovative robotic system in action.

How Automation Saved Hytrol 80% Floor Space

Hytrol, a material handling systems manufacturer, wanted to expand their capacity, but hit a growth ceiling because of the industry wide labor shortage. Acieta evaluated their current operations, and identified a custom automation solution to help Hytrol maintain their reputation as a world class material handling solutions provider, and continue to expand operations to meet increasing demand. The result was a fully remodeled floor: the Factory of the Future. Hytrol saved 80% floor space, reduced lead times, improved on time delivery, and increased capacity by 50% as a result of automation and are now more competitive in the marketplace.

Read More

Hytrol, a material handling systems manufacturer, wanted to expand their capacity, but hit a growth ceiling because of the industry wide labor shortage. Acieta evaluated their current operations, and identified a custom automation solution to help Hytrol maintain their reputation as a world class material handling solutions provider, and continue to expand operations to meet increasing demand. The result was a fully remodeled floor: the Factory of the Future. Hytrol saved 80% floor space, reduced lead times, improved on time delivery, and increased capacity by 50% as a result of automation and are now more competitive in the marketplace.

Hytrol, a material handling systems manufacturer, wanted to expand their capacity, but hit a growth ceiling because of the industry wide labor shortage. Acieta evaluated their current operations, and identified a custom automation solution to help Hytrol maintain their reputation as a world class material handling solutions provider, and continue to expand operations to meet increasing demand. The result was a fully remodeled floor: the Factory of the Future. Hytrol saved 80% floor space, reduced lead times, improved on time delivery, and increased capacity by 50% as a result of automation and are now more competitive in the marketplace.

Productivity Up and the Lights Off at Wagner Machine Company

A new lean robotic cell from Acieta helped Wagner Machine Company nearly triple their production by continuing to work when operators go home. Visit acieta.com and wagner-machine.com for more information.

Read More

A new lean robotic cell from Acieta helped Wagner Machine Company nearly triple their production by continuing to work when operators go home. Visit acieta.com and wagner-machine.com for more information.

A new lean robotic cell from Acieta helped Wagner Machine Company nearly triple their production by continuing to work when operators go home. Visit acieta.com and wagner-machine.com for more information.

Meet Wagner Machine Company’s Newest Employee, The Lean Machine

A FANUC robot system from Acieta has doubled production rates and achieved a 12-month ROI for machine shop Wagner. Find out how in this short video. Visit acieta.com for more information.

Read More

A FANUC robot system from Acieta has doubled production rates and achieved a 12-month ROI for machine shop Wagner. Find out how in this short video. Visit acieta.com for more information.

A FANUC robot system from Acieta has doubled production rates and achieved a 12-month ROI for machine shop Wagner. Find out how in this short video. Visit acieta.com for more information.

Company Moves To State-Of-The-Art Automation To Improve Efficiency And Worker Training

Acieta installed a RIBS (Robotically Integrated Bending Solutions) system at the Chassis Division of Lippert Components, Inc., in Goshen, Indiana. The new automated press brake system improves efficiency, reduces costs and facilitates team member training. Video courtesy of Lippert Components.

Read More

Acieta installed a RIBS (Robotically Integrated Bending Solutions) system at the Chassis Division of Lippert Components, Inc., in Goshen, Indiana. The new automated press brake system improves efficiency, reduces costs and facilitates team member training. Video courtesy of Lippert Components.

Acieta installed a RIBS (Robotically Integrated Bending Solutions) system at the Chassis Division of Lippert Components, Inc., in Goshen, Indiana. The new automated press brake system improves efficiency, reduces costs and facilitates team member training. Video courtesy of Lippert Components.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: