How do you send off a robotics industry legend who’s retiring after nearly four decades in the robotics industry? Have a party and invite hundreds of his closest friends and colleagues. John Burg, Founder Emeritus at Acieta, enjoyed the day filled with fun, food, music, and memories on July 14, 2022 at Acieta’s facility in Council Bluffs, Iowa.

Videos

Acieta Celebrates Retirement for Founder John Burg

How do you send off a robotics industry legend who’s retiring after nearly four decades in the robotics industry? Have a party and invite hundreds of his closest friends and colleagues. John Burg, Founder Emeritus at Acieta, enjoyed the day filled with fun, food, music, and memories on July 14, 2022 at Acieta’s facility in Council Bluffs, Iowa.

Read More

How do you send off a robotics industry legend who’s retiring after nearly four decades in the robotics industry? Have a party and invite hundreds of his closest friends and colleagues. John Burg, Founder Emeritus at Acieta, enjoyed the day filled with fun, food, music, and memories on July 14, 2022 at Acieta’s facility in Council Bluffs, Iowa.

Acieta FastLOAD CX1000 – Twice the Productivity with a Fast ROI

The FastLOAD CX1000 can operate up to two different machines simultaneously for optimal throughput. Most shops see an ROI in 6 to 12 months*. (*Average ROI utilizing 2 shifts)

Read More

The FastLOAD CX1000 can operate up to two different machines simultaneously for optimal throughput. Most shops see an ROI in 6 to 12 months*. (*Average ROI utilizing 2 shifts)

The FastLOAD CX1000 can operate up to two different machines simultaneously for optimal throughput. Most shops see an ROI in 6 to 12 months*. (*Average ROI utilizing 2 shifts)

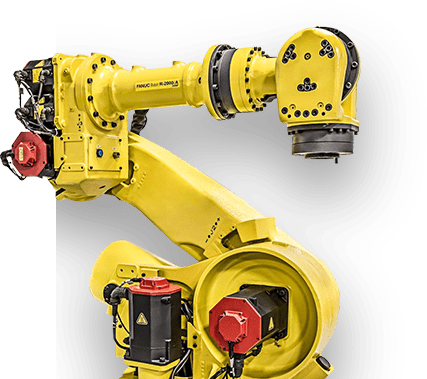

FastBEND Gives Manufacturers Instant Advantage

Operating press brakes is a potentially dangerous part of sheet metal forming and metal part fabrication. But what if you could produce more, higher-quality parts without adding risk to your workers? The FastBEND® robotic cell can be integrated with new or existing press brakes to process a wide variety of formed parts.

Read More

Operating press brakes is a potentially dangerous part of sheet metal forming and metal part fabrication. But what if you could produce more, higher-quality parts without adding risk to your workers? The FastBEND® robotic cell can be integrated with new or existing press brakes to process a wide variety of formed parts.

Operating press brakes is a potentially dangerous part of sheet metal forming and metal part fabrication. But what if you could produce more, higher-quality parts without adding risk to your workers? The FastBEND® robotic cell can be integrated with new or existing press brakes to process a wide variety of formed parts.

Legends Are Forever: Robotics Pioneer Retires After Growing The Industry For Four Decades

An industry legend. A pioneer. A visionary. All those words describe John Burg, who has been integral in expanding the use of robotics in the manufacturing industry for the last four decades. John’s retirement in February 2022 marks the end of an era. He began his legacy in the 1980s, a time when no one but the big automotive OEMs were using robots to improve operations. John saw the future of robotics as a technology adoptable by small and medium manufacturers as well, and he began a long journey to help grow robotics become what it is today: affordable, smarter, faster and accessible to all.

Read More

An industry legend. A pioneer. A visionary. All those words describe John Burg, who has been integral in expanding the use of robotics in the manufacturing industry for the last four decades. John’s retirement in February 2022 marks the end of an era. He began his legacy in the 1980s, a time when no one but the big automotive OEMs were using robots to improve operations. John saw the future of robotics as a technology adoptable by small and medium manufacturers as well, and he began a long journey to help grow robotics become what it is today: affordable, smarter, faster and accessible to all.

An industry legend. A pioneer. A visionary. All those words describe John Burg, who has been integral in expanding the use of robotics in the manufacturing industry for the last four decades. John’s retirement in February 2022 marks the end of an era. He began his legacy in the 1980s, a time when no one but the big automotive OEMs were using robots to improve operations. John saw the future of robotics as a technology adoptable by small and medium manufacturers as well, and he began a long journey to help grow robotics become what it is today: affordable, smarter, faster and accessible to all.

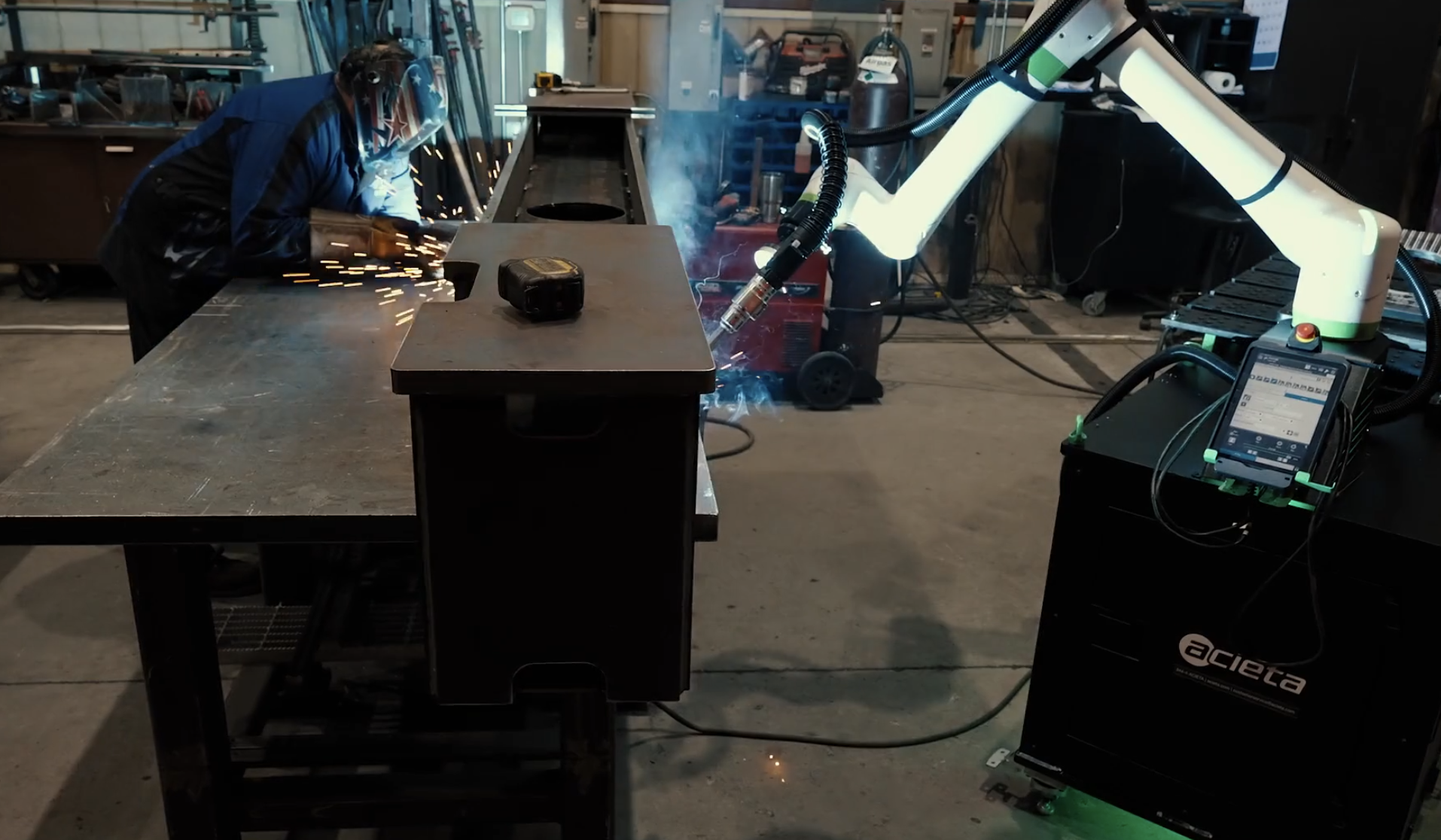

Fabricator Achieves Optimal Quality and Productivity With A Welding Robot

Fab shop MDS Manufacturing originally thought they were too small to afford a robot, but then they installed a FastARC 2HT standard robotic welding solution. Now they save a lot of time on processing, keep the lines running without roadblocks, eliminate the need for most rework, and have relieved fatigue from repetitive work for the manual welding operators.

Read More

Fab shop MDS Manufacturing originally thought they were too small to afford a robot, but then they installed a FastARC 2HT standard robotic welding solution. Now they save a lot of time on processing, keep the lines running without roadblocks, eliminate the need for most rework, and have relieved fatigue from repetitive work for the manual welding operators.

Fab shop MDS Manufacturing originally thought they were too small to afford a robot, but then they installed a FastARC 2HT standard robotic welding solution. Now they save a lot of time on processing, keep the lines running without roadblocks, eliminate the need for most rework, and have relieved fatigue from repetitive work for the manual welding operators.

Robotic Welding Increases Productivity at MDS

Robotic welding helps increase productivity and reduce workers' repetitive welding tasks. The FastARC 2HT standard robotic welding solution from Acieta provides high-quality, accurate and repeatable welds all day, every day. See how MDS Manufacturing uses the FastARC 2HT robotic welding solution to do the repetitive welding and keep workers happy.

Read More

Robotic welding helps increase productivity and reduce workers' repetitive welding tasks. The FastARC 2HT standard robotic welding solution from Acieta provides high-quality, accurate and repeatable welds all day, every day. See how MDS Manufacturing uses the FastARC 2HT robotic welding solution to do the repetitive welding and keep workers happy.

Robotic welding helps increase productivity and reduce workers' repetitive welding tasks. The FastARC 2HT standard robotic welding solution from Acieta provides high-quality, accurate and repeatable welds all day, every day. See how MDS Manufacturing uses the FastARC 2HT robotic welding solution to do the repetitive welding and keep workers happy.

Acieta FastLOAD CX1000 – Expandable and Flexible Cobot Solution

Freedom and flexibility in this small package enables you to take on more and varied projects never leaving a machine idle. Check out the Acieta FastLOAD CX1000 in action!

Read More

Freedom and flexibility in this small package enables you to take on more and varied projects never leaving a machine idle. Check out the Acieta FastLOAD CX1000 in action!

Freedom and flexibility in this small package enables you to take on more and varied projects never leaving a machine idle. Check out the Acieta FastLOAD CX1000 in action!

How to Program an Acieta FastARC Robotic Welding System

This quick guide gives you the simple steps to start up and program a new FastARC robotic welding system with a FANUC Arc Mate robot. Learn how to set the controller, name programs, set up safety features, and reset after a safety fault.

Read More

This quick guide gives you the simple steps to start up and program a new FastARC robotic welding system with a FANUC Arc Mate robot. Learn how to set the controller, name programs, set up safety features, and reset after a safety fault.

This quick guide gives you the simple steps to start up and program a new FastARC robotic welding system with a FANUC Arc Mate robot. Learn how to set the controller, name programs, set up safety features, and reset after a safety fault.

How To Set Up An Acieta Fastarc Robotic Welding System (ST, TT, DT models)

This quick start guide gives you 7 simple steps to set up a your new Acieta FastARC robotic welding system (ST, TT, DT models). Get tips on how to go from unboxing to system start-up...fast.

Read More

This quick start guide gives you 7 simple steps to set up a your new Acieta FastARC robotic welding system (ST, TT, DT models). Get tips on how to go from unboxing to system start-up...fast.

This quick start guide gives you 7 simple steps to set up a your new Acieta FastARC robotic welding system (ST, TT, DT models). Get tips on how to go from unboxing to system start-up...fast.

Simple Drag And Drop Robot Programming Has Never Been Easier!

Check out this very simple drag and drop robot programming available on the FastLOAD CX1000 standard collaborative expandable cell! Get a virtual or in-person demo today - info@acieta.com | 844-4-ACIETA. /cx1000/

Read More

Check out this very simple drag and drop robot programming available on the FastLOAD CX1000 standard collaborative expandable cell! Get a virtual or in-person demo today - info@acieta.com | 844-4-ACIETA. /cx1000/

Check out this very simple drag and drop robot programming available on the FastLOAD CX1000 standard collaborative expandable cell! Get a virtual or in-person demo today - info@acieta.com | 844-4-ACIETA. /cx1000/

Mobile Collaborative Robot Provides Freedom & Flexibility On The Shop Floor

Jake Corning demonstrates how to use the easiest, most flexible cobot ever--the FastLOAD CX1000. Watch as workers wheel the cart-mounted robot into place, set it up in seconds, quickly replace snap-on grippers, and program the system with an intuitive touch screen interface. It’s the collaborative robot everyone can use.

Read More

Jake Corning demonstrates how to use the easiest, most flexible cobot ever--the FastLOAD CX1000. Watch as workers wheel the cart-mounted robot into place, set it up in seconds, quickly replace snap-on grippers, and program the system with an intuitive touch screen interface. It’s the collaborative robot everyone can use.

Jake Corning demonstrates how to use the easiest, most flexible cobot ever--the FastLOAD CX1000. Watch as workers wheel the cart-mounted robot into place, set it up in seconds, quickly replace snap-on grippers, and program the system with an intuitive touch screen interface. It’s the collaborative robot everyone can use.

Get Production Back Up To Speed

Now is a challenging time for companies to recover fast and get production back up to speed to stay competitive in the market. For machine shops facing capacity challenges, labor shortages and quality variability, Acieta introduces the new FastLOAD® DR2000 robotic cell, which can be ready for delivery in 8 weeks. Address core business challenges, fast. Low commitment, fast entry to automation. Fast lead time.

Read More

Now is a challenging time for companies to recover fast and get production back up to speed to stay competitive in the market. For machine shops facing capacity challenges, labor shortages and quality variability, Acieta introduces the new FastLOAD® DR2000 robotic cell, which can be ready for delivery in 8 weeks. Address core business challenges, fast. Low commitment, fast entry to automation. Fast lead time.

Now is a challenging time for companies to recover fast and get production back up to speed to stay competitive in the market. For machine shops facing capacity challenges, labor shortages and quality variability, Acieta introduces the new FastLOAD® DR2000 robotic cell, which can be ready for delivery in 8 weeks. Address core business challenges, fast. Low commitment, fast entry to automation. Fast lead time.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: